2026 Boratas BSTE Series

Année

Année

2026

Condition

Condition

Neuf

Survivre

La Description

Boratas BSTE Series Stationary Vibrating Screens are engineered screening units designed to classify bulk materials by size in quarry, mining, recycling, and aggregate processing applications. These screens support accurate material separation essential to downstream crushing and final product grading.

The screens are typically used in fixed crushing and screening facilities where efficient separation and product sizing are critical. They can be integrated into multi-stage plants or operate independently for material classification tasks.

Boratas stationary vibrating screens are available in multiple configurations with 2, 3, or 4 decks, covering a broad range of throughput requirements and end-product specifications. Capacities vary with screen size and deck count, accommodating from lower throughput classification up to higher capacity screening needs.

Manufactured in compliance with international quality standards and supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en/products/stationary-vibrating-screen

******************************************************************

Main Components:

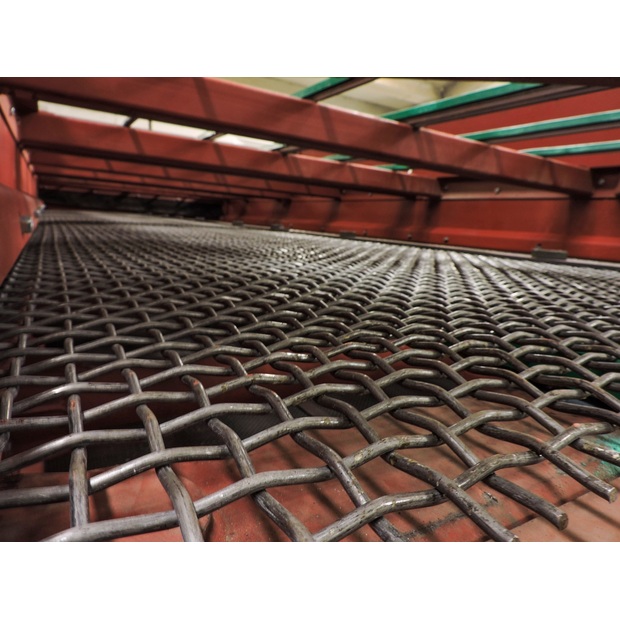

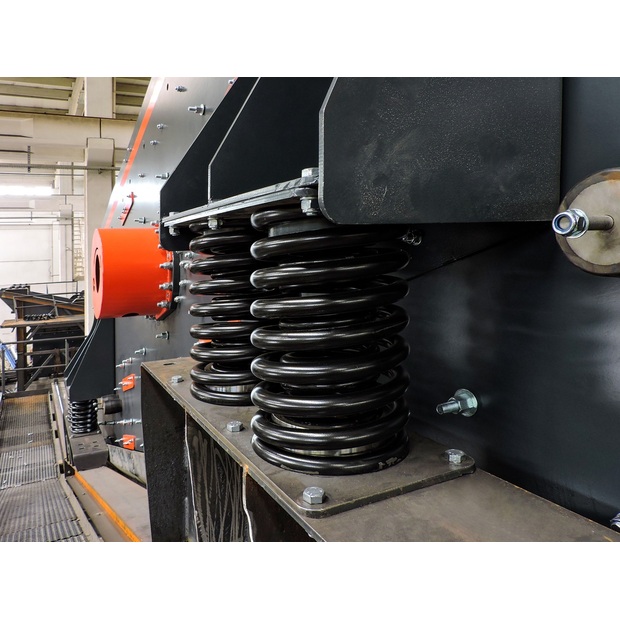

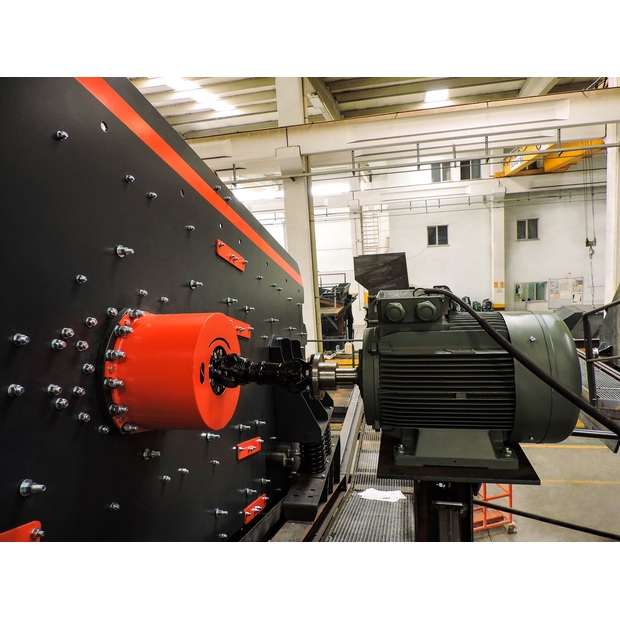

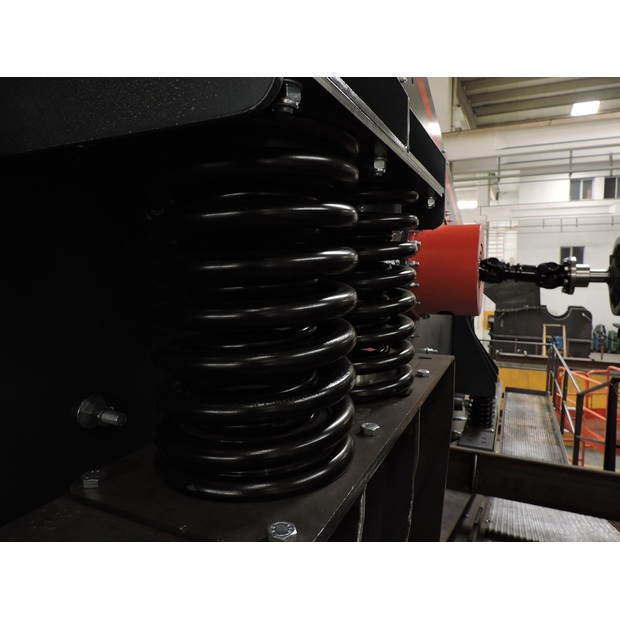

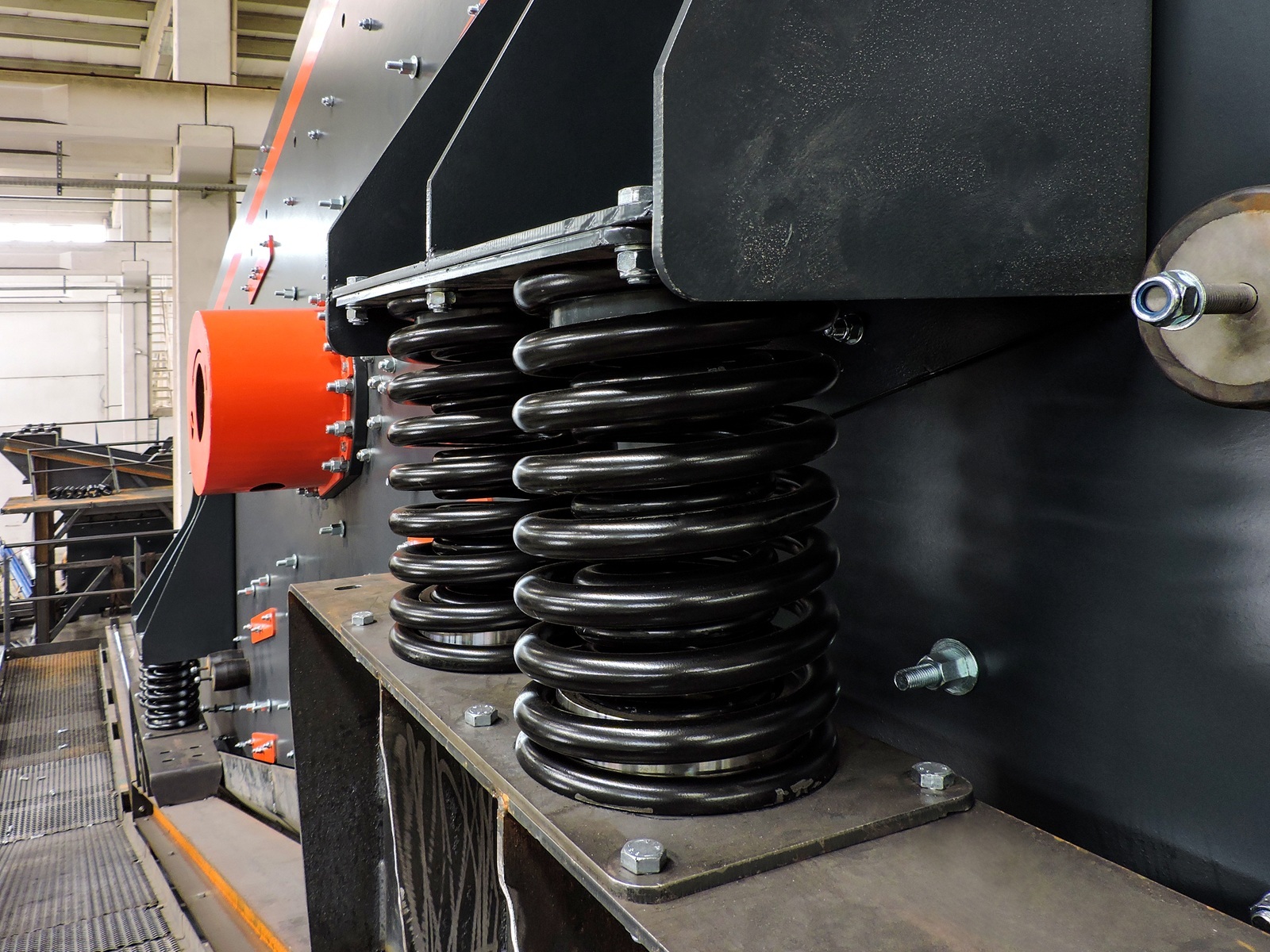

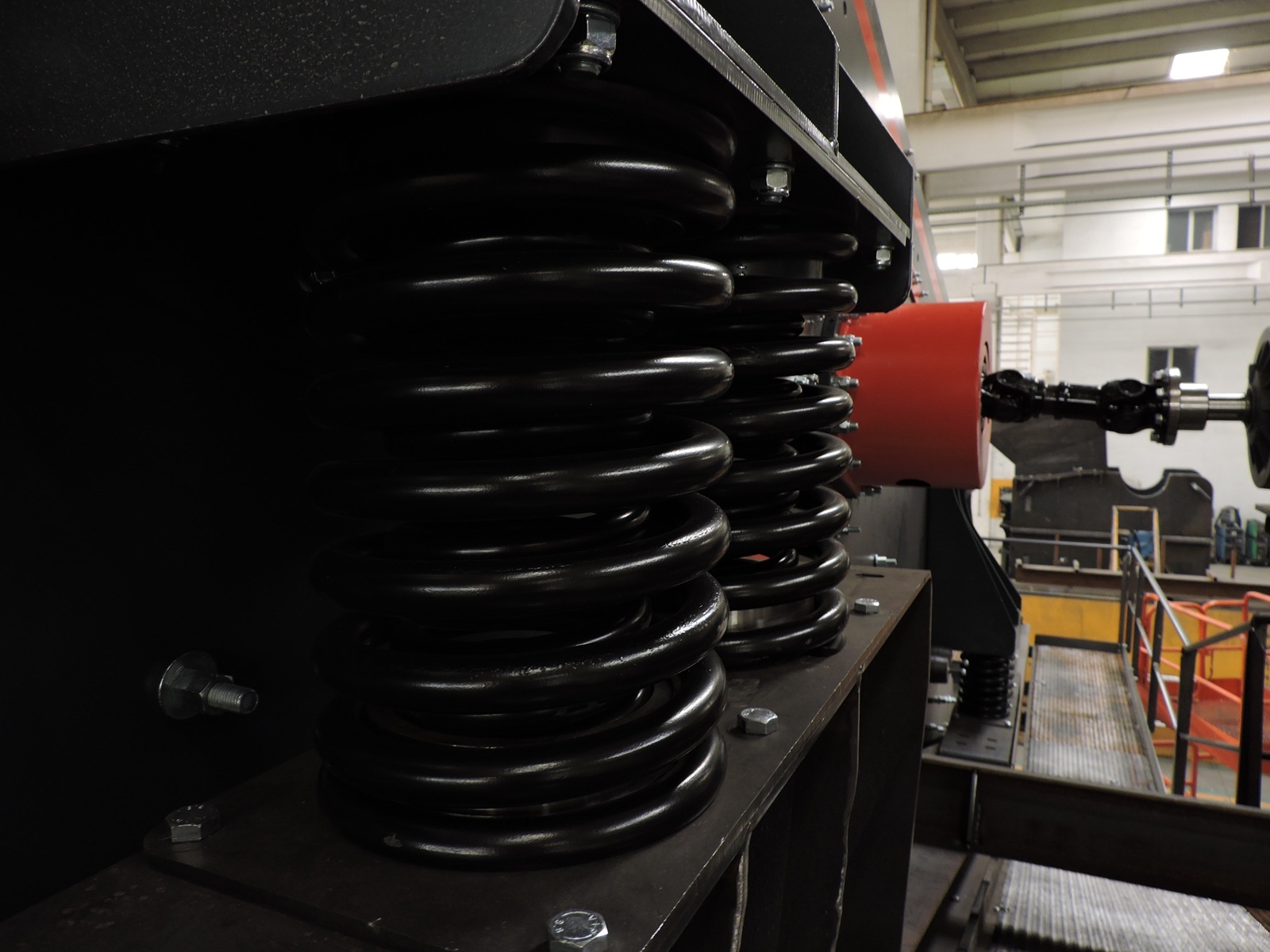

Inclined vibrating screen unit with 2–4 decks, eccentric shaft with counterweights, vibration motors, replaceable screen media, structural frame with support springs and bearings, discharge chutes.

Key Features

1. Multi-Deck Screening Flexibility Configurable with 2, 3, or 4 decks to support multiple product size outputs in a single unit.

2. Circular Vibrating Motion Eccentric shaft-driven vibration system provides smooth, disturbance-free material movement for reliable screening performance.

3. Efficient Material Classification Designed to enhance separation accuracy, improving overall plant throughput and product quality.

4. Easy Maintenance and Mesh Change Wide deck spacing and accessible tensioning system make screen mesh replacement straightforward and fast.

5. Robust Construction Heavy-duty frame and quality bearings ensure long service life under continuous operation.

6. Electric Drive Power System Screen motors are separately powered for controlled, efficient operation across configurations.

Boratas BSTE Series Stationary Vibrating Screens are engineered screening units designed to classify bulk materials by size in quarry, mining, recycling, and aggregate processing applications. These screens support accurate material separation essential to downstream crushing and final product grading.

The screens are typically used in fixed crushing and screening facilities where efficient separation and product sizing are critical. They can be integrated into multi-stage plants or operate independently for material classification tasks.

Boratas stationary vibrating screens are available in multiple configurations with 2, 3, or 4 decks, covering a broad range of throughput requirements and end-product specifications. Capacities vary with screen size and deck count, accommodating from lower throughput classification up to higher capacity screening needs.

Manufactured in compliance with international quality standards and supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en/products/stationary-vibrating-screen

******************************************************************

Main Components:

Inclined vibrating screen unit with 2–4 decks, eccentric shaft with counterweights, vibration motors, replaceable screen media, structural frame with support springs and bearings, discharge chutes.

Key Features

1. Multi-Deck Screening Flexibility Configurable with 2, 3, or 4 decks to support multiple product size outputs in a single unit.

2. Circular Vibrating Motion Eccentric shaft-driven vibration system provides smooth, disturbance-free material movement for reliable screening performance.

3. Efficient Material Classification Designed to enhance separation accuracy, improving overall plant throughput and product quality.

4. Easy Maintenance and Mesh Change Wide deck spacing and accessible tensioning system make screen mesh replacement straightforward and fast.

5. Robust Construction Heavy-duty frame and quality bearings ensure long service life under continuous operation.

6. Electric Drive Power System Screen motors are separately powered for controlled, efficient operation across configurations.

Montre plus Montrer moins

Équipement De Construction

Équipement De Construction

Grues

Grues

Manutention

Manutention

Camions et remorques

Camions et remorques

Véhicules

Véhicules

Équipement Agricole

Équipement Agricole

Enchères en Direct

Enchères en Direct