2026 Boratas BDW1545

Année

Année

2026

Condition

Condition

Neuf

Survivre

La Description

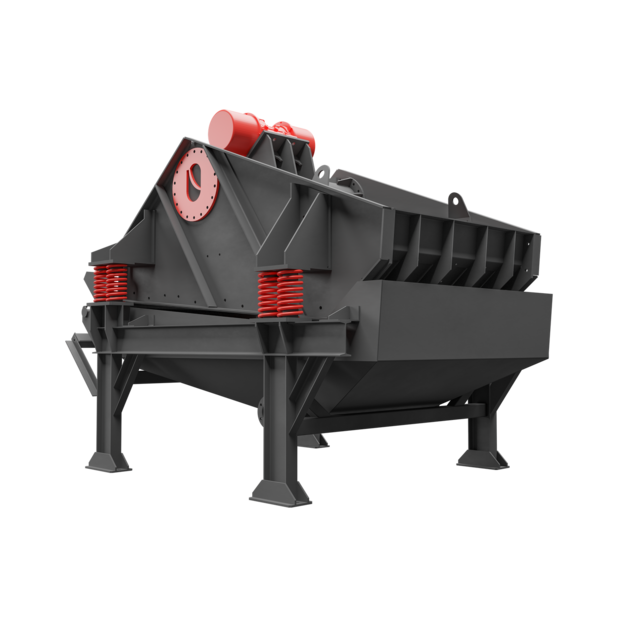

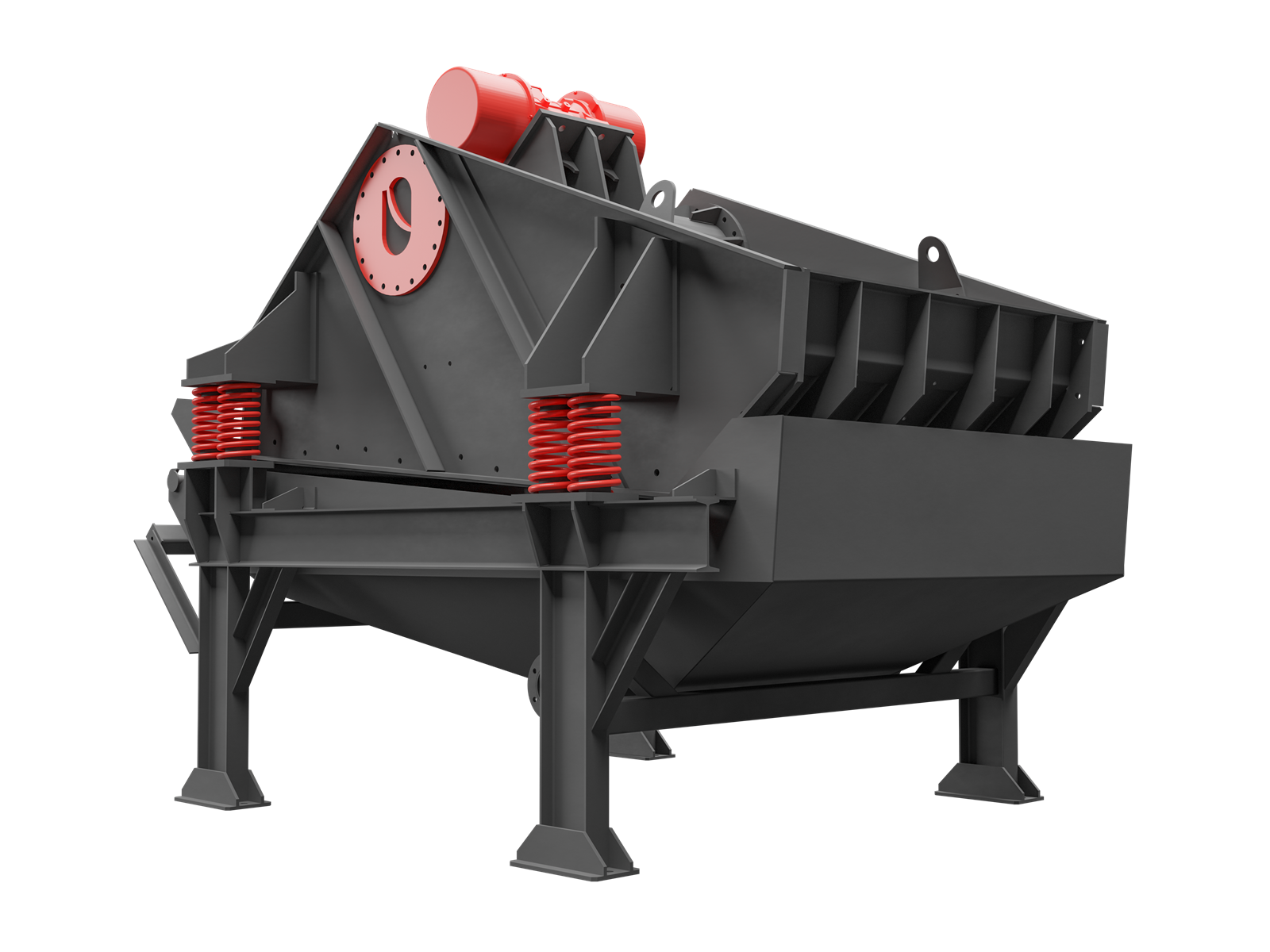

Boratas BDW1545 Dewatering Screen is a stationary dewatering unit designed for moisture reduction of sand and fine aggregates in quarry, mining, and washing plant applications. It is used after washing equipment such as bucket wheel washers or washing screens to deliver cleaner material with reduced water content.

The BDW1545 is intended for fixed wash plants where high dewatering efficiency and stable throughput are required. Its linear vibration system supports effective water separation while retaining fine material on the screen surface.

Powered by two 7.5 kW electric motors, the BDW1545 delivers consistent vibration and reliable performance under continuous operating conditions. The compact yet robust structure ensures operational stability while supporting capacities up to 200 tph.

Technical Specifications

• Screen Dimensions: 1500 x 4500 mm

• Capacity: approx. 100 – 200 tph

• Drive Power: 2 x 7.5 kW

• Weight: approx. 4,500 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

******************************************************************

Standard Features

• 1500 x 4500 mm dewatering screen surface

• Linear vibration system

• Dual 7.5 kW electric drive motors

• High-capacity dewatering performance

• Heavy-duty structural construction

Optional Features

• Different screen mesh sizes and materials

• Dust cover systems

• Adjustable spray bars

• Automatic lubrication system

Key Features

1. High Dewatering Efficiency

Linear vibration and optimized screen design reduce final moisture content while maintaining material throughput.

2. Stable Linear Motion System

Dual-motor drive ensures uniform vibration and consistent material movement across the screen.

3. Fine Material Retention

Screen geometry supports efficient drainage while keeping fine particles on the screening surface.

4. Industrial-Grade Construction

Reinforced frame and durable components support long-term use in demanding wash plant environments.

5. Maintenance-Friendly Design

Accessible components and wear-resistant parts simplify routine service and reduce downtime.

Boratas BDW1545 Dewatering Screen is a stationary dewatering unit designed for moisture reduction of sand and fine aggregates in quarry, mining, and washing plant applications. It is used after washing equipment such as bucket wheel washers or washing screens to deliver cleaner material with reduced water content.

The BDW1545 is intended for fixed wash plants where high dewatering efficiency and stable throughput are required. Its linear vibration system supports effective water separation while retaining fine material on the screen surface.

Powered by two 7.5 kW electric motors, the BDW1545 delivers consistent vibration and reliable performance under continuous operating conditions. The compact yet robust structure ensures operational stability while supporting capacities up to 200 tph.

Technical Specifications

• Screen Dimensions: 1500 x 4500 mm

• Capacity: approx. 100 – 200 tph

• Drive Power: 2 x 7.5 kW

• Weight: approx. 4,500 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

******************************************************************

Standard Features

• 1500 x 4500 mm dewatering screen surface

• Linear vibration system

• Dual 7.5 kW electric drive motors

• High-capacity dewatering performance

• Heavy-duty structural construction

Optional Features

• Different screen mesh sizes and materials

• Dust cover systems

• Adjustable spray bars

• Automatic lubrication system

Key Features

1. High Dewatering Efficiency

Linear vibration and optimized screen design reduce final moisture content while maintaining material throughput.

2. Stable Linear Motion System

Dual-motor drive ensures uniform vibration and consistent material movement across the screen.

3. Fine Material Retention

Screen geometry supports efficient drainage while keeping fine particles on the screening surface.

4. Industrial-Grade Construction

Reinforced frame and durable components support long-term use in demanding wash plant environments.

5. Maintenance-Friendly Design

Accessible components and wear-resistant parts simplify routine service and reduce downtime.

The BDW1545 is intended for fixed wash plants where high dewatering efficiency and stable throughput are required. Its linear vibration system supports effective water separation while retaining fine material on the screen surface.

Powered by two 7.5 kW electric motors, the BDW1545 delivers consistent vibration and reliable performance under continuous operating conditions. The compact yet robust structure ensures operational stability while supporting capacities up to 200 tph.

Technical Specifications

• Screen Dimensions: 1500 x 4500 mm

• Capacity: approx. 100 – 200 tph

• Drive Power: 2 x 7.5 kW

• Weight: approx. 4,500 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

******************************************************************

Standard Features

• 1500 x 4500 mm dewatering screen surface

• Linear vibration system

• Dual 7.5 kW electric drive motors

• High-capacity dewatering performance

• Heavy-duty structural construction

Optional Features

• Different screen mesh sizes and materials

• Dust cover systems

• Adjustable spray bars

• Automatic lubrication system

Key Features

1. High Dewatering Efficiency

Linear vibration and optimized screen design reduce final moisture content while maintaining material throughput.

2. Stable Linear Motion System

Dual-motor drive ensures uniform vibration and consistent material movement across the screen.

3. Fine Material Retention

Screen geometry supports efficient drainage while keeping fine particles on the screening surface.

4. Industrial-Grade Construction

Reinforced frame and durable components support long-term use in demanding wash plant environments.

5. Maintenance-Friendly Design

Accessible components and wear-resistant parts simplify routine service and reduce downtime.

Montre plus Montrer moins

Équipement De Construction

Équipement De Construction

Grues

Grues

Manutention

Manutention

Camions et remorques

Camions et remorques

Véhicules

Véhicules

Équipement Agricole

Équipement Agricole

Enchères en Direct

Enchères en Direct