2026 Boratas VSI900

Year

Year

2026

Condition

Condition

New

Overview

Description

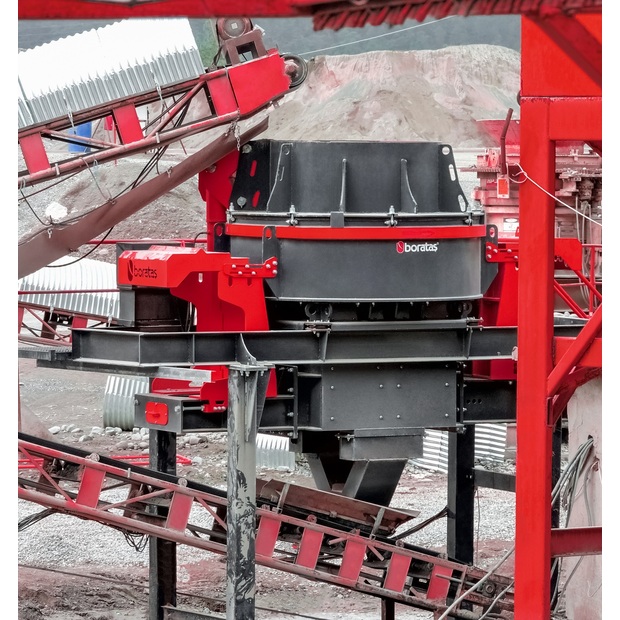

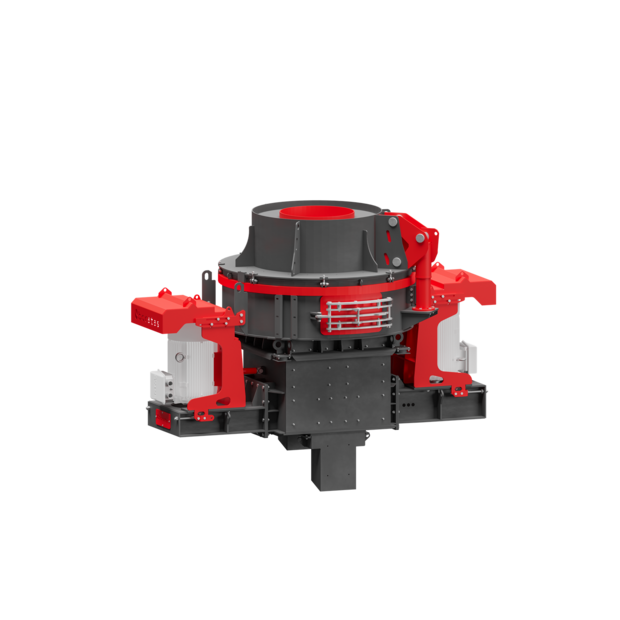

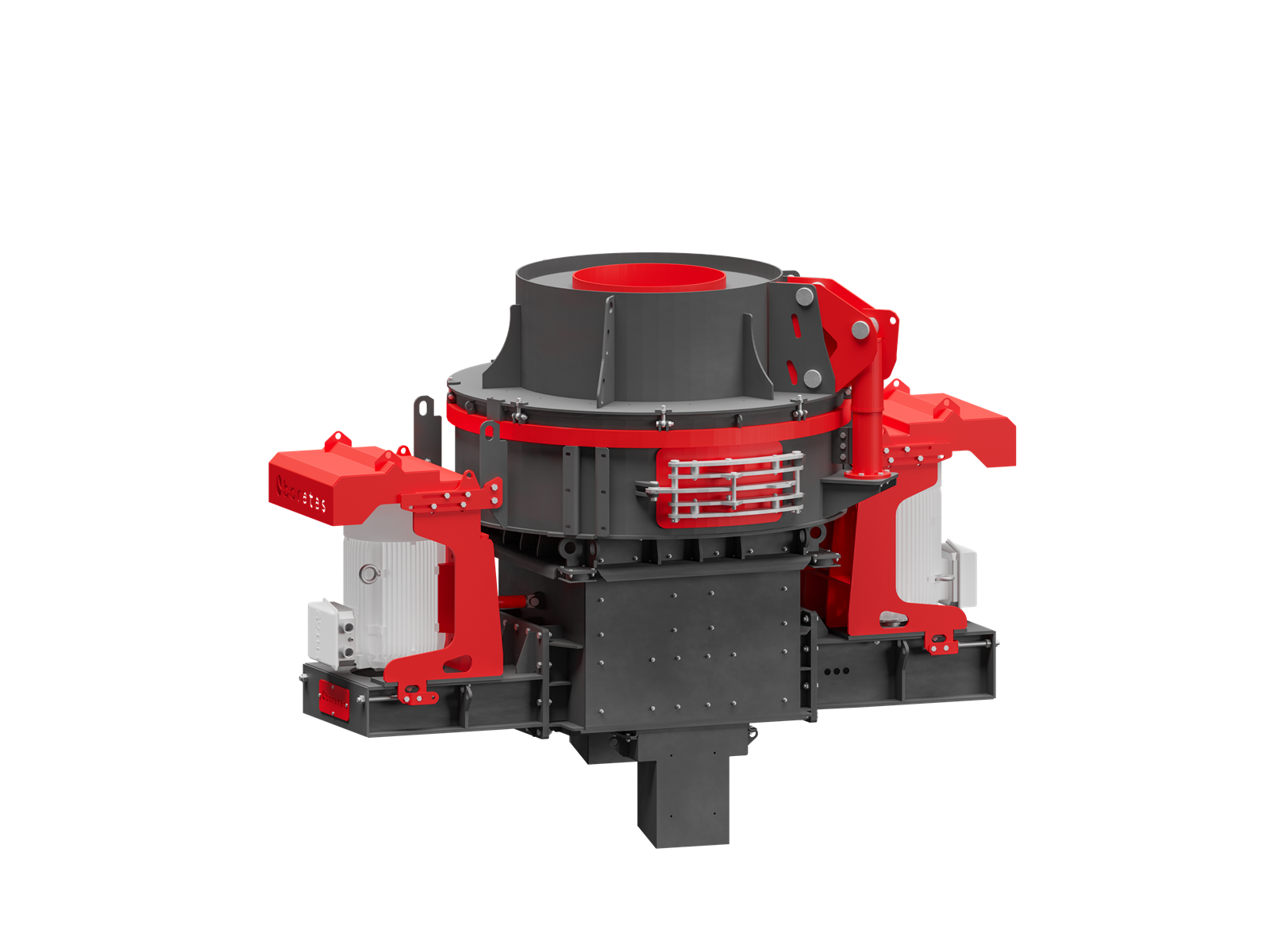

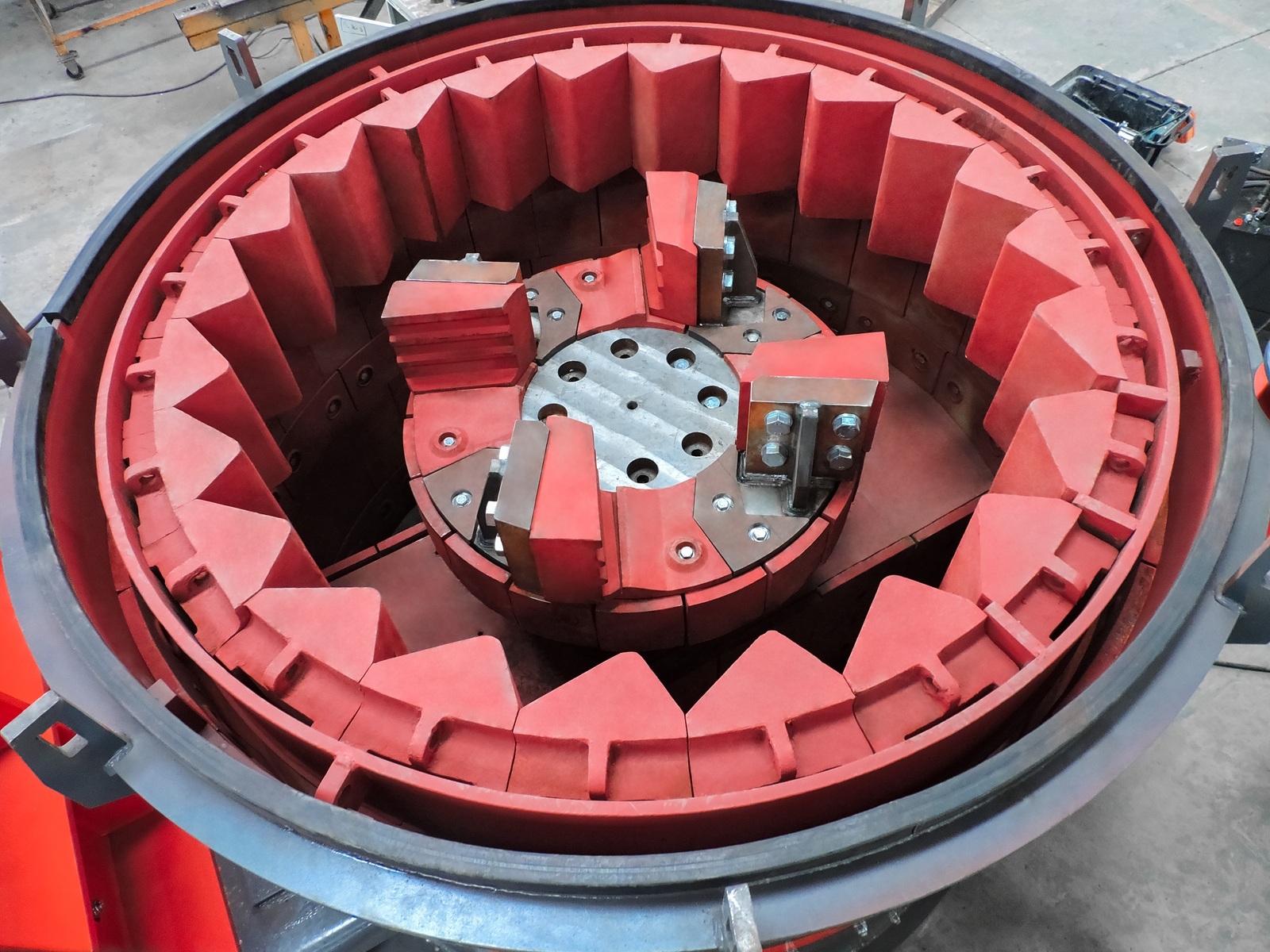

Boratas VSI900 Vertical Shaft Impact Crusher is a stationary VSI crusher designed for final-stage crushing, shaping, and sand production in quarry, mining, and aggregate processing applications. It is engineered to deliver consistent cubical product for concrete, asphalt, and high-quality aggregate production.

The VSI900 is intended for tertiary or quaternary crushing stages where precise shaping and controlled particle size are required. It processes feed material up to 38 mm and is commonly installed after jaw or cone crushers in multi-stage crushing plants.

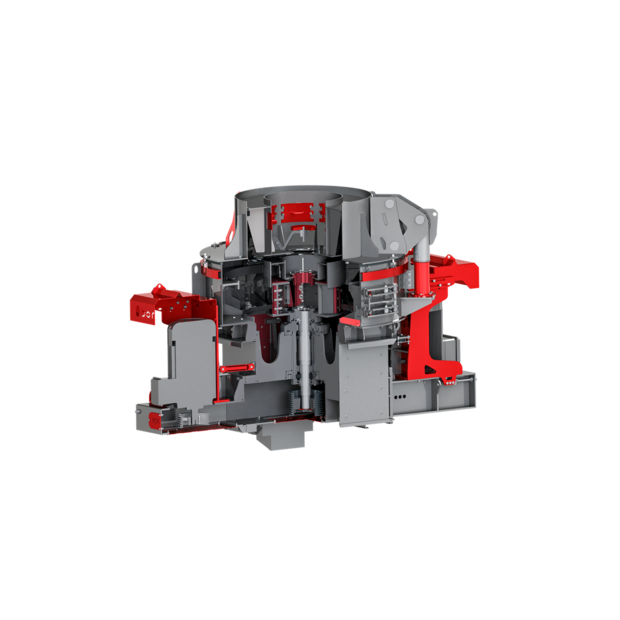

Equipped with a 900 mm closed rotor, the VSI900 operates using rock-on-rock or rock-on-steel crushing principles. This allows operators to balance wear cost, energy efficiency, and final product shape depending on material characteristics and application needs. Adjustable rotor speed provides flexibility for different throughput and grading requirements.

Technical Specifications

• Rotor Diameter: 900 mm

• Max. Feed Size: 38 mm

• Capacity: approx. 100 – 300 tph

• Motor Power: 160 – 200 – 250 kW

• Weight: approx. 14,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

******************************************************************

Standard Features:

• 900 mm enclosed rotor

• 160–250 kW motor

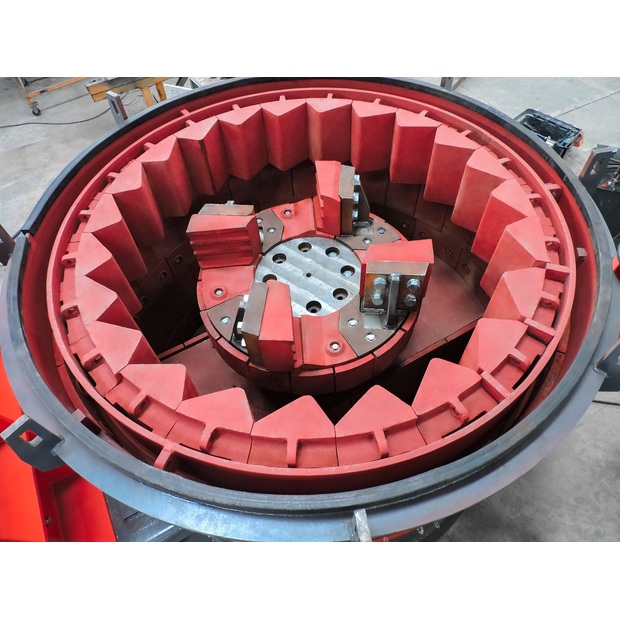

• Rock-on-rock or rock-on-steel crushing setup

• Replaceable anvils and wear parts

• Top-mounted access for maintenance

• Adjustable rotor speed

Optional Features:

• Vibration sensor and monitoring unit

• Automatic lubrication system

• Dust suppression spray system

• Smart control panel integration

Key Features

1. Consistent Cubical Product Shape

Designed to produce high-quality cubical material, suitable for concrete, asphalt, and manufactured sand applications.

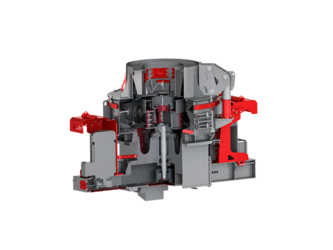

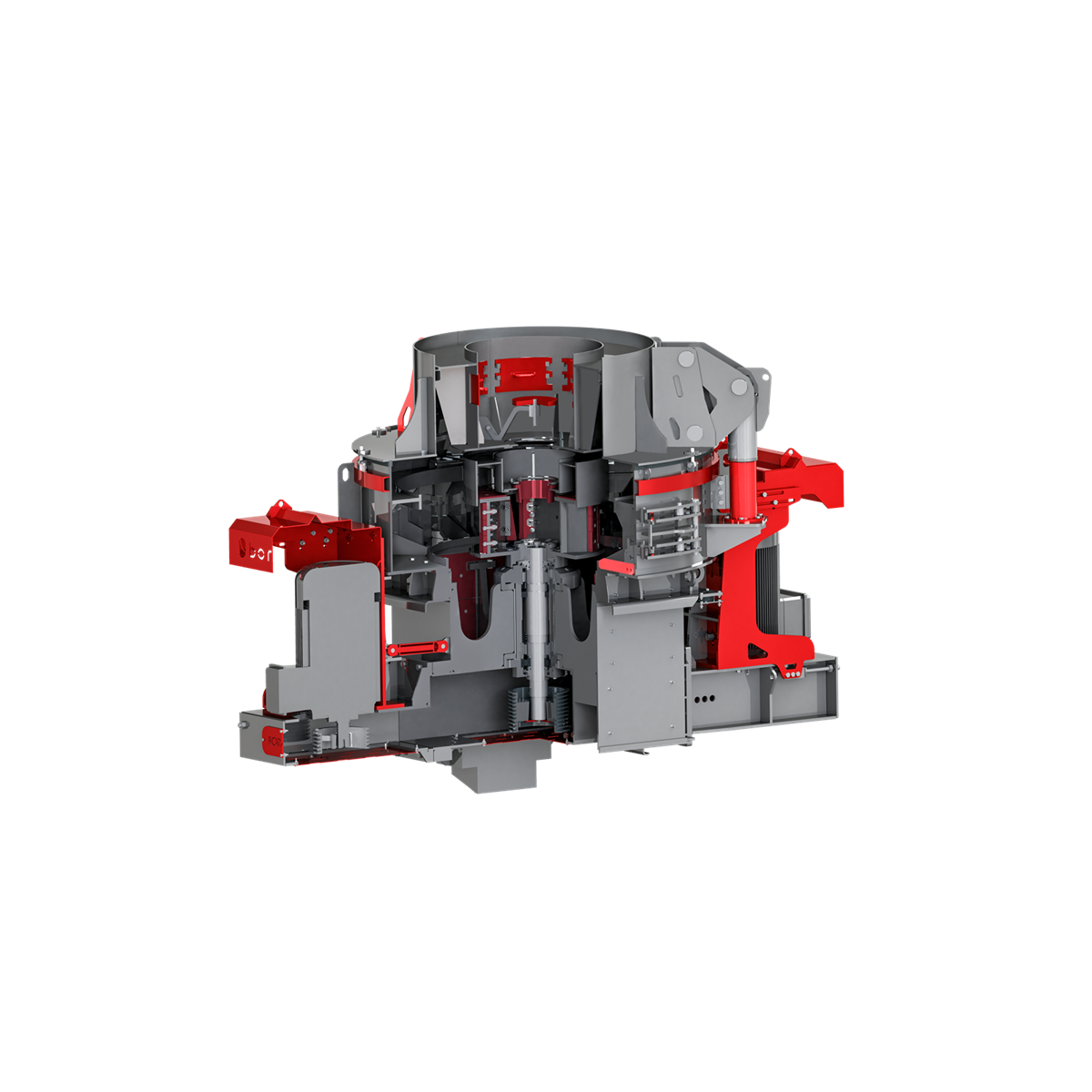

2. Closed Rotor Crushing System

Enclosed rotor design improves energy efficiency, stabilizes material flow, and reduces wear under continuous operation.

3. Adjustable Crushing Performance

Rotor speed and crushing configuration can be adjusted to control particle shape, grading, and throughput.

4. Rock-on-Rock or Rock-on-Steel Operation

Flexible crushing principle allows optimization based on abrasiveness, wear cost, and final product requirements.

5. Maintenance-Friendly Design

Top-mounted access and modular internal components enable fast inspection and replacement of wear parts.

6. Compact Installation Footprint

Suitable for fixed and semi-mobile crushing plants where space efficiency and high output are required.

Boratas VSI900 Vertical Shaft Impact Crusher is a stationary VSI crusher designed for final-stage crushing, shaping, and sand production in quarry, mining, and aggregate processing applications. It is engineered to deliver consistent cubical product for concrete, asphalt, and high-quality aggregate production.

The VSI900 is intended for tertiary or quaternary crushing stages where precise shaping and controlled particle size are required. It processes feed material up to 38 mm and is commonly installed after jaw or cone crushers in multi-stage crushing plants.

Equipped with a 900 mm closed rotor, the VSI900 operates using rock-on-rock or rock-on-steel crushing principles. This allows operators to balance wear cost, energy efficiency, and final product shape depending on material characteristics and application needs. Adjustable rotor speed provides flexibility for different throughput and grading requirements.

Technical Specifications

• Rotor Diameter: 900 mm

• Max. Feed Size: 38 mm

• Capacity: approx. 100 – 300 tph

• Motor Power: 160 – 200 – 250 kW

• Weight: approx. 14,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

******************************************************************

Standard Features:

• 900 mm enclosed rotor

• 160–250 kW motor

• Rock-on-rock or rock-on-steel crushing setup

• Replaceable anvils and wear parts

• Top-mounted access for maintenance

• Adjustable rotor speed

Optional Features:

• Vibration sensor and monitoring unit

• Automatic lubrication system

• Dust suppression spray system

• Smart control panel integration

Key Features

1. Consistent Cubical Product Shape

Designed to produce high-quality cubical material, suitable for concrete, asphalt, and manufactured sand applications.

2. Closed Rotor Crushing System

Enclosed rotor design improves energy efficiency, stabilizes material flow, and reduces wear under continuous operation.

3. Adjustable Crushing Performance

Rotor speed and crushing configuration can be adjusted to control particle shape, grading, and throughput.

4. Rock-on-Rock or Rock-on-Steel Operation

Flexible crushing principle allows optimization based on abrasiveness, wear cost, and final product requirements.

5. Maintenance-Friendly Design

Top-mounted access and modular internal components enable fast inspection and replacement of wear parts.

6. Compact Installation Footprint

Suitable for fixed and semi-mobile crushing plants where space efficiency and high output are required.

The VSI900 is intended for tertiary or quaternary crushing stages where precise shaping and controlled particle size are required. It processes feed material up to 38 mm and is commonly installed after jaw or cone crushers in multi-stage crushing plants.

Equipped with a 900 mm closed rotor, the VSI900 operates using rock-on-rock or rock-on-steel crushing principles. This allows operators to balance wear cost, energy efficiency, and final product shape depending on material characteristics and application needs. Adjustable rotor speed provides flexibility for different throughput and grading requirements.

Technical Specifications

• Rotor Diameter: 900 mm

• Max. Feed Size: 38 mm

• Capacity: approx. 100 – 300 tph

• Motor Power: 160 – 200 – 250 kW

• Weight: approx. 14,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

******************************************************************

Standard Features:

• 900 mm enclosed rotor

• 160–250 kW motor

• Rock-on-rock or rock-on-steel crushing setup

• Replaceable anvils and wear parts

• Top-mounted access for maintenance

• Adjustable rotor speed

Optional Features:

• Vibration sensor and monitoring unit

• Automatic lubrication system

• Dust suppression spray system

• Smart control panel integration

Key Features

1. Consistent Cubical Product Shape

Designed to produce high-quality cubical material, suitable for concrete, asphalt, and manufactured sand applications.

2. Closed Rotor Crushing System

Enclosed rotor design improves energy efficiency, stabilizes material flow, and reduces wear under continuous operation.

3. Adjustable Crushing Performance

Rotor speed and crushing configuration can be adjusted to control particle shape, grading, and throughput.

4. Rock-on-Rock or Rock-on-Steel Operation

Flexible crushing principle allows optimization based on abrasiveness, wear cost, and final product requirements.

5. Maintenance-Friendly Design

Top-mounted access and modular internal components enable fast inspection and replacement of wear parts.

6. Compact Installation Footprint

Suitable for fixed and semi-mobile crushing plants where space efficiency and high output are required.

Show more Show less

Construction Equipment

Construction Equipment

Cranes

Cranes

Material Handling

Material Handling

Trucks & Trailers

Trucks & Trailers

Vehicles

Vehicles

Agricultural Equipment

Agricultural Equipment

Live Auctions

Live Auctions