2026 Boratas BLH14

Year

Year

2026

Condition

Condition

New

Overview

Description

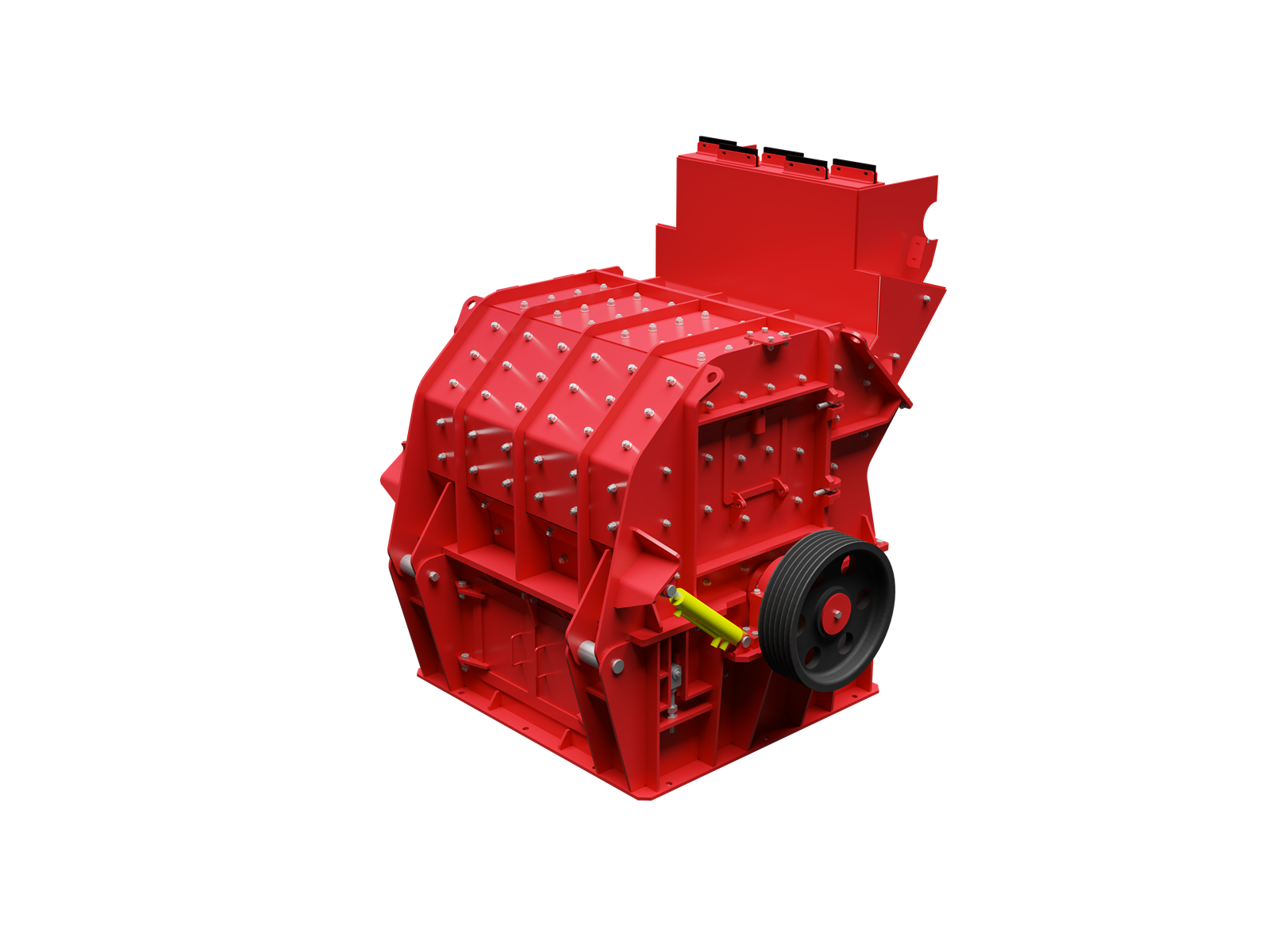

Boratas BLH14 Wheeled Mobile Hammer Crusher is a mobile hammer crusher unit designed for high reduction of soft to medium-hard, non-abrasive materials. It is commonly used in quarrying, construction, demolition, and recycling applications where compact crushing and flexible site operation are required.

The BLH14 is intended for secondary or tertiary crushing stages. Thanks to its integrated grizzly screen located beneath the crushing chamber, the unit can often produce final material without the need for a separate screening plant. Product size can be controlled by adjusting rotor speed and the gap between the rotor and the lower grate, allowing accurate output sizing based on project requirements.

Mounted on a wheeled mobile chassis, the BLH14 is suitable for temporary quarry operations and short-term projects where fast relocation and quick setup are critical. Hydraulic positioning of the chassis, feed hopper, and belt conveyors enables the unit to be installed and ready for operation in a short time, reducing transport and installation costs compared to stationary crushing plants.

Technical Specifications

• Capacity: 30 – 80 tph

• Max. Feed Size: 50 mm

• Rotor Diameter: Ø1000 mm

• Rotor Width: 1400 mm

• Weight: approx. 20,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

Hammer crusher unit with high-speed rotor and replaceable hammers, integrated grizzly screen, wheeled mobile chassis, feed hopper, discharge conveyor, PLC control system, electric drive system.

Key Features

1. High-Reduction Hammer Crushing

Heavy-duty hammer crusher design delivers strong impact force for efficient size reduction and consistent product output.

2. Integrated Grizzly Screening

Built-in grizzly screen enables direct production of final material, reducing the need for additional screening equipment.

3. Adjustable Product Size Control

Rotor speed and grate gap adjustment allow precise control of output particle size for different applications.

4. Wheeled Mobile Configuration

Wheel-mounted chassis supports easy transport, fast relocation, and quick site setup for temporary or mobile crushing operations.

5. PLC-Based Control System

Automation system enables simple monitoring and adjustment of crusher parameters, improving operational safety and efficiency.

6. Electric Drive Operation

Electric power system supports stable performance with lower operating and maintenance costs.

Optional Features

• Hardox-lined feed hopper

• Automatic lubrication system

• Magnetic metal separator

• Dust suppression system

Boratas BLH14 Wheeled Mobile Hammer Crusher is a mobile hammer crusher unit designed for high reduction of soft to medium-hard, non-abrasive materials. It is commonly used in quarrying, construction, demolition, and recycling applications where compact crushing and flexible site operation are required.

The BLH14 is intended for secondary or tertiary crushing stages. Thanks to its integrated grizzly screen located beneath the crushing chamber, the unit can often produce final material without the need for a separate screening plant. Product size can be controlled by adjusting rotor speed and the gap between the rotor and the lower grate, allowing accurate output sizing based on project requirements.

Mounted on a wheeled mobile chassis, the BLH14 is suitable for temporary quarry operations and short-term projects where fast relocation and quick setup are critical. Hydraulic positioning of the chassis, feed hopper, and belt conveyors enables the unit to be installed and ready for operation in a short time, reducing transport and installation costs compared to stationary crushing plants.

Technical Specifications

• Capacity: 30 – 80 tph

• Max. Feed Size: 50 mm

• Rotor Diameter: Ø1000 mm

• Rotor Width: 1400 mm

• Weight: approx. 20,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

Hammer crusher unit with high-speed rotor and replaceable hammers, integrated grizzly screen, wheeled mobile chassis, feed hopper, discharge conveyor, PLC control system, electric drive system.

Key Features

1. High-Reduction Hammer Crushing

Heavy-duty hammer crusher design delivers strong impact force for efficient size reduction and consistent product output.

2. Integrated Grizzly Screening

Built-in grizzly screen enables direct production of final material, reducing the need for additional screening equipment.

3. Adjustable Product Size Control

Rotor speed and grate gap adjustment allow precise control of output particle size for different applications.

4. Wheeled Mobile Configuration

Wheel-mounted chassis supports easy transport, fast relocation, and quick site setup for temporary or mobile crushing operations.

5. PLC-Based Control System

Automation system enables simple monitoring and adjustment of crusher parameters, improving operational safety and efficiency.

6. Electric Drive Operation

Electric power system supports stable performance with lower operating and maintenance costs.

Optional Features

• Hardox-lined feed hopper

• Automatic lubrication system

• Magnetic metal separator

• Dust suppression system

The BLH14 is intended for secondary or tertiary crushing stages. Thanks to its integrated grizzly screen located beneath the crushing chamber, the unit can often produce final material without the need for a separate screening plant. Product size can be controlled by adjusting rotor speed and the gap between the rotor and the lower grate, allowing accurate output sizing based on project requirements.

Mounted on a wheeled mobile chassis, the BLH14 is suitable for temporary quarry operations and short-term projects where fast relocation and quick setup are critical. Hydraulic positioning of the chassis, feed hopper, and belt conveyors enables the unit to be installed and ready for operation in a short time, reducing transport and installation costs compared to stationary crushing plants.

Technical Specifications

• Capacity: 30 – 80 tph

• Max. Feed Size: 50 mm

• Rotor Diameter: Ø1000 mm

• Rotor Width: 1400 mm

• Weight: approx. 20,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

Hammer crusher unit with high-speed rotor and replaceable hammers, integrated grizzly screen, wheeled mobile chassis, feed hopper, discharge conveyor, PLC control system, electric drive system.

Key Features

1. High-Reduction Hammer Crushing

Heavy-duty hammer crusher design delivers strong impact force for efficient size reduction and consistent product output.

2. Integrated Grizzly Screening

Built-in grizzly screen enables direct production of final material, reducing the need for additional screening equipment.

3. Adjustable Product Size Control

Rotor speed and grate gap adjustment allow precise control of output particle size for different applications.

4. Wheeled Mobile Configuration

Wheel-mounted chassis supports easy transport, fast relocation, and quick site setup for temporary or mobile crushing operations.

5. PLC-Based Control System

Automation system enables simple monitoring and adjustment of crusher parameters, improving operational safety and efficiency.

6. Electric Drive Operation

Electric power system supports stable performance with lower operating and maintenance costs.

Optional Features

• Hardox-lined feed hopper

• Automatic lubrication system

• Magnetic metal separator

• Dust suppression system

Show more Show less

Construction Equipment

Construction Equipment

Cranes

Cranes

Material Handling

Material Handling

Trucks & Trailers

Trucks & Trailers

Vehicles

Vehicles

Agricultural Equipment

Agricultural Equipment

Live Auctions

Live Auctions