2026 Boratas BPJ120

2026 Boratas BPJ120

السنة

السنة

٢٠٢٦

حالة المعدة

حالة المعدة

جديد

نظرة عامة

الوصف

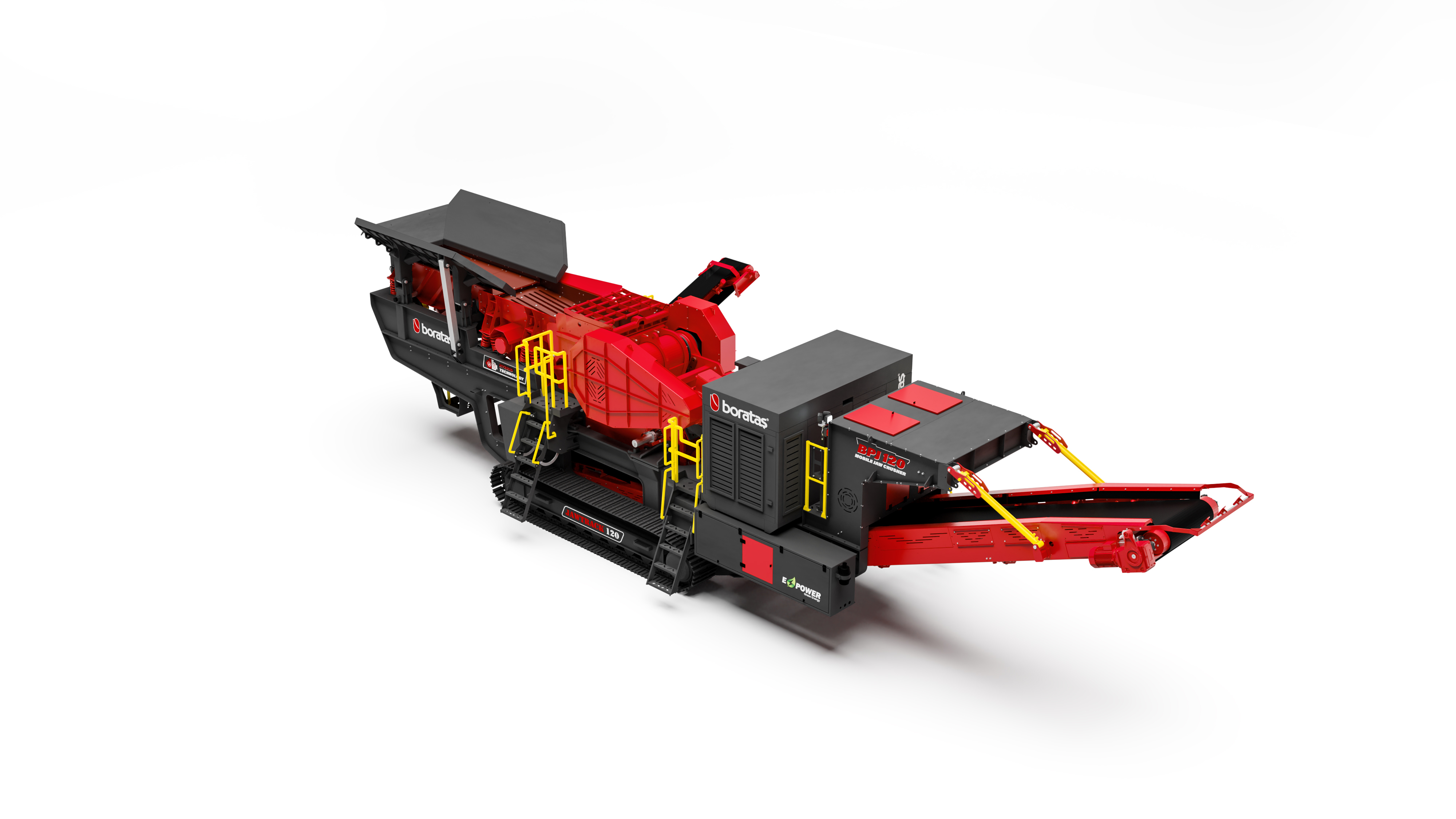

Boratas Jawtrack Series Mobile Jaw Crusher BPJ120 is a tracked jaw crusher designed for high-capacity material crushing in mining, quarrying, and recycling applications. Combining compactness, mobility, and high crushing performance, the BPJ120 delivers reliable operation and consistent output under demanding site conditions.

Equipped with a single-toggle jaw crusher from the proven BCK jaw series, the BPJ120 is capable of processing a wide range of materials, from hard and abrasive natural stone such as granite and basalt to asphalt, concrete, and construction waste for recycling applications. This versatility allows efficient material reduction into reusable end products.

The Boratas Jawtrack BPJ120 crawler jaw crusher is available in standard and customizable configurations, allowing adaptation to specific operational needs, feed characteristics, and project requirements.

Hybrid (Diesel–Electric) Power System

The BPJ120 utilizes a hybrid power concept combining electric drive efficiency with an integrated diesel generator. This system reduces fuel consumption, lowers operating costs, and enables independent operation on both powered sites and remote locations, without compromising crushing performance.

Technical Specifications

• Capacity: 150–400 tph

• Feed Opening: 1,200 × 700 mm

• Operating Weight: 58,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

• High-capacity jaw crusher

• Electric or diesel-electric drive system

• Vibrating feeder with double-deck pre-screen

• Hydraulically foldable bypass side conveyor

• Hydraulically foldable side and rear hopper covers

• PLC-based control system

• Wireless remote control

• Drum motors for conveyors

• Integrated lighting tower

Key Features and Differentiators

1. Robust Jaw Crushing Mechanism

The BPJ120 is equipped with a durable jaw crusher designed for efficient and precise material reduction. Its reinforced structure and optimized crushing motion improve throughput while maintaining consistent product quality.

2. Adjustable Crushing Settings

Multiple adjustable crusher settings allow operators to adapt the machine to different feed sizes and material characteristics, providing full control over the crushing process and final product size.

3. Operator-Oriented Design

Easy-access maintenance points and simplified cleaning procedures reduce downtime and improve serviceability. The intuitive control system supports smooth operation and efficient machine management.

4. Mobility and Site Flexibility

As a tracked mobile jaw crusher, the BPJ120 offers excellent maneuverability and fast setup across diverse work sites. On-site material processing reduces haulage requirements and logistical costs.

5. Hybrid Diesel–Electric Power System

The hybrid power system combines the advantages of electric operation with on-site energy independence, resulting in lower fuel consumption, reduced emissions, and minimized maintenance requirements.

6. Jaw Crusher Unit Design

The Closed Side Setting (CSS) is hydraulically adjustable for precise control of the final product size. The motor base is chassis-mounted to minimize V-belt length, while an integrated hydraulic cylinder allows fast and easy V-belt replacement, improving service efficiency and wear part life.

Boratas Jawtrack Series Mobile Jaw Crusher BPJ120 is a tracked jaw crusher designed for high-capacity material crushing in mining, quarrying, and recycling applications. Combining compactness, mobility, and high crushing performance, the BPJ120 delivers reliable operation and consistent output under demanding site conditions.

Equipped with a single-toggle jaw crusher from the proven BCK jaw series, the BPJ120 is capable of processing a wide range of materials, from hard and abrasive natural stone such as granite and basalt to asphalt, concrete, and construction waste for recycling applications. This versatility allows efficient material reduction into reusable end products.

The Boratas Jawtrack BPJ120 crawler jaw crusher is available in standard and customizable configurations, allowing adaptation to specific operational needs, feed characteristics, and project requirements.

Hybrid (Diesel–Electric) Power System

The BPJ120 utilizes a hybrid power concept combining electric drive efficiency with an integrated diesel generator. This system reduces fuel consumption, lowers operating costs, and enables independent operation on both powered sites and remote locations, without compromising crushing performance.

Technical Specifications

• Capacity: 150–400 tph

• Feed Opening: 1,200 × 700 mm

• Operating Weight: 58,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

• High-capacity jaw crusher

• Electric or diesel-electric drive system

• Vibrating feeder with double-deck pre-screen

• Hydraulically foldable bypass side conveyor

• Hydraulically foldable side and rear hopper covers

• PLC-based control system

• Wireless remote control

• Drum motors for conveyors

• Integrated lighting tower

Key Features and Differentiators

1. Robust Jaw Crushing Mechanism

The BPJ120 is equipped with a durable jaw crusher designed for efficient and precise material reduction. Its reinforced structure and optimized crushing motion improve throughput while maintaining consistent product quality.

2. Adjustable Crushing Settings

Multiple adjustable crusher settings allow operators to adapt the machine to different feed sizes and material characteristics, providing full control over the crushing process and final product size.

3. Operator-Oriented Design

Easy-access maintenance points and simplified cleaning procedures reduce downtime and improve serviceability. The intuitive control system supports smooth operation and efficient machine management.

4. Mobility and Site Flexibility

As a tracked mobile jaw crusher, the BPJ120 offers excellent maneuverability and fast setup across diverse work sites. On-site material processing reduces haulage requirements and logistical costs.

5. Hybrid Diesel–Electric Power System

The hybrid power system combines the advantages of electric operation with on-site energy independence, resulting in lower fuel consumption, reduced emissions, and minimized maintenance requirements.

6. Jaw Crusher Unit Design

The Closed Side Setting (CSS) is hydraulically adjustable for precise control of the final product size. The motor base is chassis-mounted to minimize V-belt length, while an integrated hydraulic cylinder allows fast and easy V-belt replacement, improving service efficiency and wear part life.

Equipped with a single-toggle jaw crusher from the proven BCK jaw series, the BPJ120 is capable of processing a wide range of materials, from hard and abrasive natural stone such as granite and basalt to asphalt, concrete, and construction waste for recycling applications. This versatility allows efficient material reduction into reusable end products.

The Boratas Jawtrack BPJ120 crawler jaw crusher is available in standard and customizable configurations, allowing adaptation to specific operational needs, feed characteristics, and project requirements.

Hybrid (Diesel–Electric) Power System

The BPJ120 utilizes a hybrid power concept combining electric drive efficiency with an integrated diesel generator. This system reduces fuel consumption, lowers operating costs, and enables independent operation on both powered sites and remote locations, without compromising crushing performance.

Technical Specifications

• Capacity: 150–400 tph

• Feed Opening: 1,200 × 700 mm

• Operating Weight: 58,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

• High-capacity jaw crusher

• Electric or diesel-electric drive system

• Vibrating feeder with double-deck pre-screen

• Hydraulically foldable bypass side conveyor

• Hydraulically foldable side and rear hopper covers

• PLC-based control system

• Wireless remote control

• Drum motors for conveyors

• Integrated lighting tower

Key Features and Differentiators

1. Robust Jaw Crushing Mechanism

The BPJ120 is equipped with a durable jaw crusher designed for efficient and precise material reduction. Its reinforced structure and optimized crushing motion improve throughput while maintaining consistent product quality.

2. Adjustable Crushing Settings

Multiple adjustable crusher settings allow operators to adapt the machine to different feed sizes and material characteristics, providing full control over the crushing process and final product size.

3. Operator-Oriented Design

Easy-access maintenance points and simplified cleaning procedures reduce downtime and improve serviceability. The intuitive control system supports smooth operation and efficient machine management.

4. Mobility and Site Flexibility

As a tracked mobile jaw crusher, the BPJ120 offers excellent maneuverability and fast setup across diverse work sites. On-site material processing reduces haulage requirements and logistical costs.

5. Hybrid Diesel–Electric Power System

The hybrid power system combines the advantages of electric operation with on-site energy independence, resulting in lower fuel consumption, reduced emissions, and minimized maintenance requirements.

6. Jaw Crusher Unit Design

The Closed Side Setting (CSS) is hydraulically adjustable for precise control of the final product size. The motor base is chassis-mounted to minimize V-belt length, while an integrated hydraulic cylinder allows fast and easy V-belt replacement, improving service efficiency and wear part life.

أظهر المزيد عرض أقل

معدات ثقيلة

معدات ثقيلة

كرينات

كرينات

مناولة العتاد

مناولة العتاد

الشاحنات والمقطورات

الشاحنات والمقطورات

مركبة تجارية

مركبة تجارية

معدات الزراعية

معدات الزراعية

مزادات مباشرة

مزادات مباشرة