2026 Boratas BPC100

2026 Boratas BPC100

السنة

السنة

٢٠٢٦

حالة المعدة

حالة المعدة

جديد

نظرة عامة

الوصف

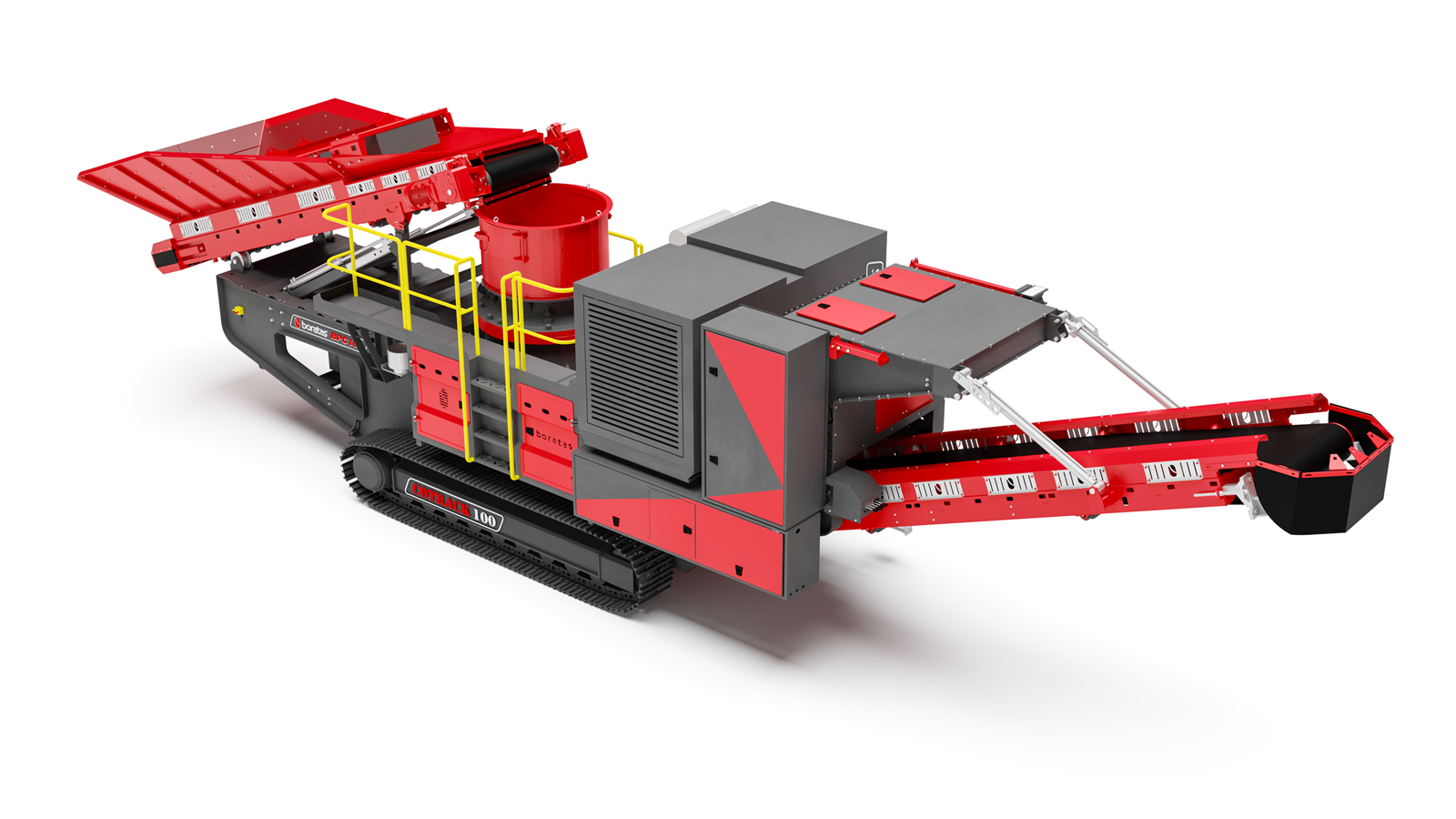

Boratas Cotrack Series Crawler Cone Crusher BPC100 is a compact, tracked cone crushing unit designed for secondary and tertiary crushing in aggregate, quarrying, mining, and recycling applications. Combining high crushing performance with full mobility, the BPC100 delivers reliable throughput and consistent cubical end-product quality when processing medium to hard natural stone.

Built on a robust crawler chassis, the BPC100 allows fast relocation between job sites and smooth integration into multi-stage crushing plants. Its balanced design makes it suitable for operations where capacity, mobility, and stable performance are equally important.

The Cotrack BPC100 is available in standard and configurable setups, enabling adaptation to specific site conditions, material characteristics, and operator requirements.

Hybrid (Diesel–Electric) Power System

Our Tracked Cone Crushers are equipped with an efficient electric drive system supported by an integrated diesel generator. This hybrid configuration enables reduced fuel consumption, lower maintenance requirements, and independent operation on both powered and remote sites without compromising crushing performance.

Technical Specifications

• Maximum Feeding Size: 42 - 214 mm

• Power: 360 kVA

• Weight: 35,000 kg

Manufactured in compliance with international quality standards. Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

******************************************************************

Main Components

• High-efficiency cone crusher unit

• Electric or diesel-electric drive system

• Track-mounted undercarriage

• PLC-based control system

• Wireless remote control

• Feed hopper and adjustable feeder

• Dust reduction system

• Drum motors for conveyors

Key Features and Differentiators

1. Efficient Crushing Performance

The BPC100 is designed to deliver consistent reduction and excellent product shape, enhancing downstream processing and final output quality.

2. Compact Mobility

Its durable track design provides reliable movement across site terrain, reducing setup time and improving site logistics.

3. Configurable Crushing Options

Standard and optional configurations allow adaptation to different material types and application needs.

4. User-Focused Design

Easy-access maintenance points and intuitive controls minimize downtime and improve operational efficiency.

5. Hybrid Power Advantage

Combining electric drive efficiency with integrated diesel power supports fuel-efficient and environmentally responsible operation.

6. Durable Construction

Built with robust components for long service life and consistent performance under challenging conditions.

Boratas Cotrack Series Crawler Cone Crusher BPC100 is a compact, tracked cone crushing unit designed for secondary and tertiary crushing in aggregate, quarrying, mining, and recycling applications. Combining high crushing performance with full mobility, the BPC100 delivers reliable throughput and consistent cubical end-product quality when processing medium to hard natural stone.

Built on a robust crawler chassis, the BPC100 allows fast relocation between job sites and smooth integration into multi-stage crushing plants. Its balanced design makes it suitable for operations where capacity, mobility, and stable performance are equally important.

The Cotrack BPC100 is available in standard and configurable setups, enabling adaptation to specific site conditions, material characteristics, and operator requirements.

Hybrid (Diesel–Electric) Power System

Our Tracked Cone Crushers are equipped with an efficient electric drive system supported by an integrated diesel generator. This hybrid configuration enables reduced fuel consumption, lower maintenance requirements, and independent operation on both powered and remote sites without compromising crushing performance.

Technical Specifications

• Maximum Feeding Size: 42 - 214 mm

• Power: 360 kVA

• Weight: 35,000 kg

Manufactured in compliance with international quality standards. Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

******************************************************************

Main Components

• High-efficiency cone crusher unit

• Electric or diesel-electric drive system

• Track-mounted undercarriage

• PLC-based control system

• Wireless remote control

• Feed hopper and adjustable feeder

• Dust reduction system

• Drum motors for conveyors

Key Features and Differentiators

1. Efficient Crushing Performance

The BPC100 is designed to deliver consistent reduction and excellent product shape, enhancing downstream processing and final output quality.

2. Compact Mobility

Its durable track design provides reliable movement across site terrain, reducing setup time and improving site logistics.

3. Configurable Crushing Options

Standard and optional configurations allow adaptation to different material types and application needs.

4. User-Focused Design

Easy-access maintenance points and intuitive controls minimize downtime and improve operational efficiency.

5. Hybrid Power Advantage

Combining electric drive efficiency with integrated diesel power supports fuel-efficient and environmentally responsible operation.

6. Durable Construction

Built with robust components for long service life and consistent performance under challenging conditions.

Built on a robust crawler chassis, the BPC100 allows fast relocation between job sites and smooth integration into multi-stage crushing plants. Its balanced design makes it suitable for operations where capacity, mobility, and stable performance are equally important.

The Cotrack BPC100 is available in standard and configurable setups, enabling adaptation to specific site conditions, material characteristics, and operator requirements.

Hybrid (Diesel–Electric) Power System

Our Tracked Cone Crushers are equipped with an efficient electric drive system supported by an integrated diesel generator. This hybrid configuration enables reduced fuel consumption, lower maintenance requirements, and independent operation on both powered and remote sites without compromising crushing performance.

Technical Specifications

• Maximum Feeding Size: 42 - 214 mm

• Power: 360 kVA

• Weight: 35,000 kg

Manufactured in compliance with international quality standards. Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

******************************************************************

Main Components

• High-efficiency cone crusher unit

• Electric or diesel-electric drive system

• Track-mounted undercarriage

• PLC-based control system

• Wireless remote control

• Feed hopper and adjustable feeder

• Dust reduction system

• Drum motors for conveyors

Key Features and Differentiators

1. Efficient Crushing Performance

The BPC100 is designed to deliver consistent reduction and excellent product shape, enhancing downstream processing and final output quality.

2. Compact Mobility

Its durable track design provides reliable movement across site terrain, reducing setup time and improving site logistics.

3. Configurable Crushing Options

Standard and optional configurations allow adaptation to different material types and application needs.

4. User-Focused Design

Easy-access maintenance points and intuitive controls minimize downtime and improve operational efficiency.

5. Hybrid Power Advantage

Combining electric drive efficiency with integrated diesel power supports fuel-efficient and environmentally responsible operation.

6. Durable Construction

Built with robust components for long service life and consistent performance under challenging conditions.

أظهر المزيد عرض أقل

معدات ثقيلة

معدات ثقيلة

كرينات

كرينات

مناولة العتاد

مناولة العتاد

الشاحنات والمقطورات

الشاحنات والمقطورات

مركبة تجارية

مركبة تجارية

معدات الزراعية

معدات الزراعية

مزادات مباشرة

مزادات مباشرة