2026 Boratas DMK Series

Année

Année

2026

Condition

Condition

Neuf

Survivre

La Description

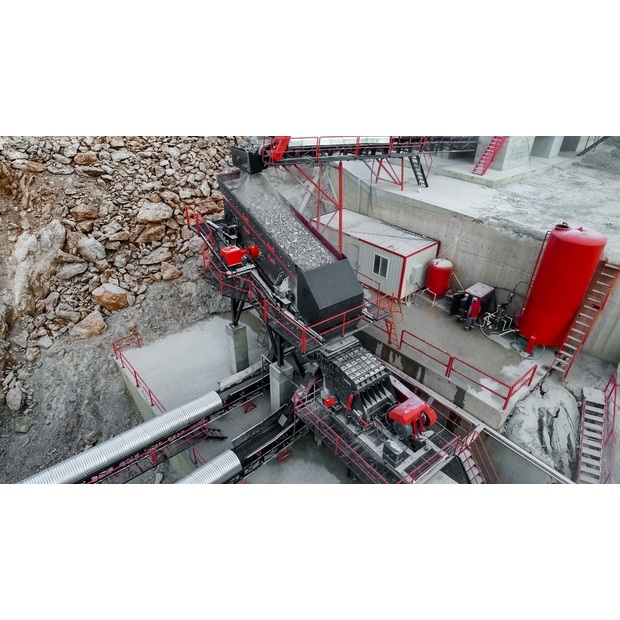

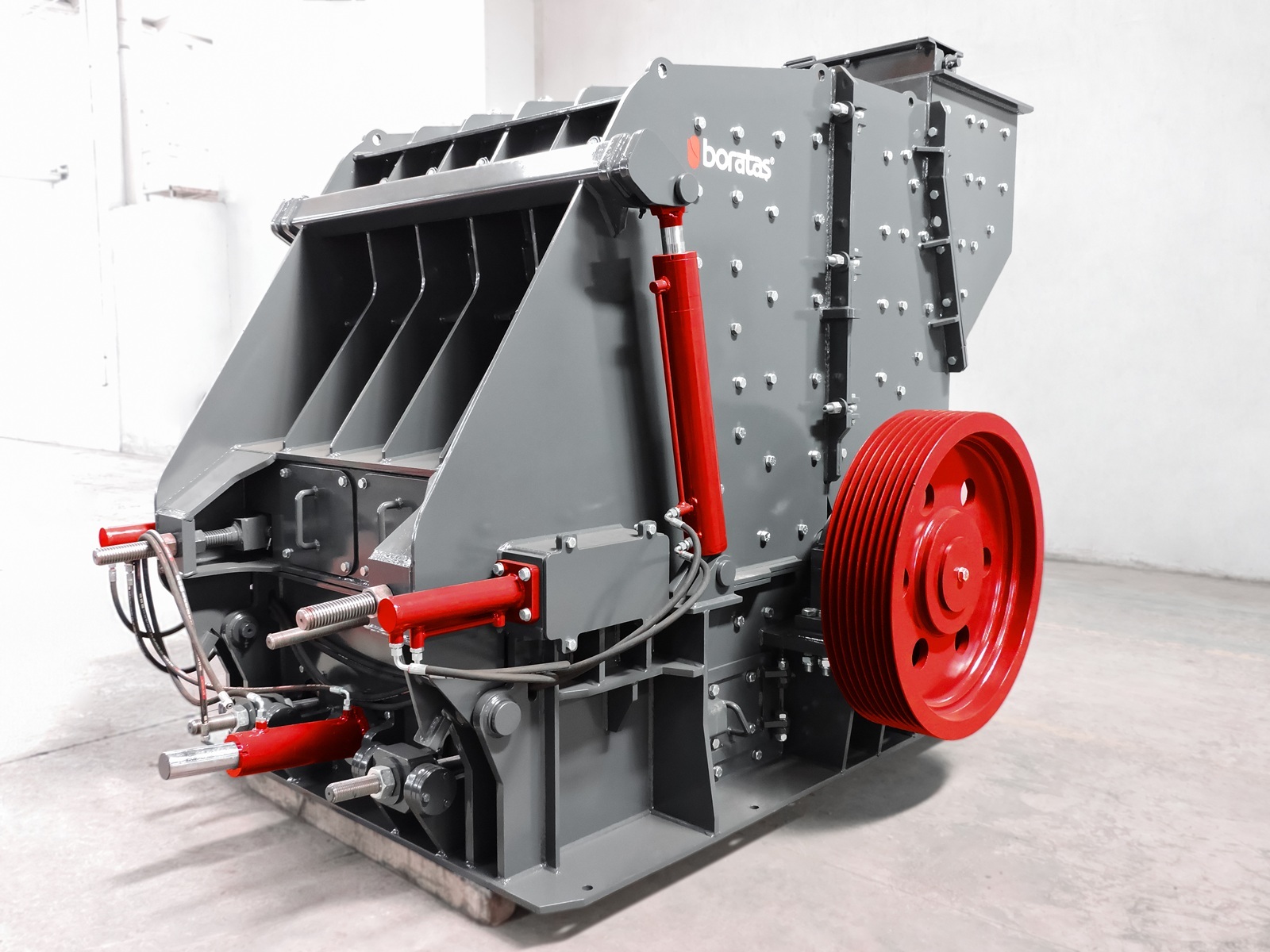

Boratas DMK Series Hard-Stone Secondary Impact Crusher is a stationary impact crusher engineered for crushing medium to high hardness materials such as limestone, granite, basalt and similar rock types in quarry, mining, and concrete aggregate applications. It is designed to produce cubical product suitable for asphalt, concrete and industrial aggregate production.

This heavy-duty impact crusher is intended for secondary crushing stages in fixed crushing and screening facilities where high reduction ratio and product shape control are required.

DMK Series crushers are available in multiple sizes with nominal capacities ranging from approximately 130 tph up to 350 tph, depending on rotor dimensions and configuration, accommodating different feed and throughput requirements across the DMK0B through DMK03 model range.

Manufactured in compliance with international quality standards and supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en/products/impact-crushers/dmk-series-hard-stone-secondary-impact-crusher

*****************************************************************

Main Components Impact crushing chamber with multi-stage impact zones, high inertia rotor with wear-resistant blow bars, fixed and movable internal liners, feed hopper, structural frame, drive system, lubrication system.

Key Features

1. Triple-Stage Impact Crushing DMK crushers use three successive impact zones in the crushing chamber to achieve high comminution and controlled product shape with enhanced cubicity.

2. High Reduction Ratio The design delivers a high reduction ratio across secondary crushing applications, improving throughput efficiency.

3. Oversize Feed Handling Large feed opening and robust rotor allow handling of oversize rock up to typical secondary crusher feed sizes without bottlenecking.

4. Cubical Product Quality The crusher delivers uniformly shaped material, suitable for asphalt and concrete aggregate specifications.

5. Low Operating and Investment Costs Simple design with easy access to wear parts and low energy requirements help reduce running costs.

6. Flexible Configuration Range Multiple model sizes allow selection based on required capacity bracket and plant layout. Further Details Crusher body consists of hydraulically accessible upper section and stationary lower section for straightforward maintenance. Wear parts are hardened for long life under abrasive conditions.

Boratas DMK Series Hard-Stone Secondary Impact Crusher is a stationary impact crusher engineered for crushing medium to high hardness materials such as limestone, granite, basalt and similar rock types in quarry, mining, and concrete aggregate applications. It is designed to produce cubical product suitable for asphalt, concrete and industrial aggregate production.

This heavy-duty impact crusher is intended for secondary crushing stages in fixed crushing and screening facilities where high reduction ratio and product shape control are required.

DMK Series crushers are available in multiple sizes with nominal capacities ranging from approximately 130 tph up to 350 tph, depending on rotor dimensions and configuration, accommodating different feed and throughput requirements across the DMK0B through DMK03 model range.

Manufactured in compliance with international quality standards and supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, visit:

https://www.boratasglobal.com/en/products/impact-crushers/dmk-series-hard-stone-secondary-impact-crusher

*****************************************************************

Main Components Impact crushing chamber with multi-stage impact zones, high inertia rotor with wear-resistant blow bars, fixed and movable internal liners, feed hopper, structural frame, drive system, lubrication system.

Key Features

1. Triple-Stage Impact Crushing DMK crushers use three successive impact zones in the crushing chamber to achieve high comminution and controlled product shape with enhanced cubicity.

2. High Reduction Ratio The design delivers a high reduction ratio across secondary crushing applications, improving throughput efficiency.

3. Oversize Feed Handling Large feed opening and robust rotor allow handling of oversize rock up to typical secondary crusher feed sizes without bottlenecking.

4. Cubical Product Quality The crusher delivers uniformly shaped material, suitable for asphalt and concrete aggregate specifications.

5. Low Operating and Investment Costs Simple design with easy access to wear parts and low energy requirements help reduce running costs.

6. Flexible Configuration Range Multiple model sizes allow selection based on required capacity bracket and plant layout. Further Details Crusher body consists of hydraulically accessible upper section and stationary lower section for straightforward maintenance. Wear parts are hardened for long life under abrasive conditions.

Montre plus Montrer moins

Équipement De Construction

Équipement De Construction

Grues

Grues

Manutention

Manutention

Camions et remorques

Camions et remorques

Véhicules

Véhicules

Équipement Agricole

Équipement Agricole

Enchères en Direct

Enchères en Direct