BOMAG BM 2000/65

Condition

Condition

Used

Overview

Description

Emission stage: Stage V / TIER4f

Weight: 59,525 lb

Performance: 630.3 hp

BM 2000/65 large planer: Simply revolutionary in the 2-metre class.

Leading the way in weight, efficiency and comfort.

BOMAG's BM 2000/65 large planer sets new standards in the 2-metre class - it is even lighter, more manoeuvrable, more cost-effective and particularly easy to operate.

The cold planer's clever design offers the operator excellent all-round visibility. A clear view of the milling edge to the front enables extremely precise milling in the track. Its slim tail improves rear visibility and hence working safety.

The BM 2000/65's sleek design results in a turning circle of only 1.7 m, making the planer highly manoeuvrable. Milling in tight bends or roundabouts is no problem with the BM 2000/65.

When milling different road surfaces, asphalt and concrete selectively, operation is intuitive. BOMAG's operating concept focuses on short navigation steps and only a few submenus. And servicing the planer is made even easier by straightforward access to all maintenance points.

Leading the way in weight, efficiency and comfort.

BOMAG's BM 2000/65 large planer sets new standards in the 2-metre class - it is even lighter, more manoeuvrable, more cost-effective and particularly easy to operate.

The cold planer's clever design offers the operator excellent all-round visibility. A clear view of the milling edge to the front enables extremely precise milling in the track. Its slim tail improves rear visibility and hence working safety.

The BM 2000/65's sleek design results in a turning circle of only 1.7 m, making the planer highly manoeuvrable. Milling in tight bends or roundabouts is no problem with the BM 2000/65.

When milling different road surfaces, asphalt and concrete selectively, operation is intuitive. BOMAG's operating concept focuses on short navigation steps and only a few submenus. And servicing the planer is made even easier by straightforward access to all maintenance points.

Fields of application

Asphalt milling is a method for removing specified layers of asphalt road pavements.

BOMAG cold milling machines are designed for selective milling of lane and ground linings made up of a wide range of asphalt and concrete compounds. The different models are particularly suited for repairs or the complete removal of motorways and major federal roads, and for rural roads and inner-city work including work on roundabouts. With different working and milling depths, large areas can be removed quickly and completely in one work stage.

Technology makes the difference.

BOMAG consistently sets industry standards and has developed numerous technologies that make everyday work easier, support machine operators and ensure high-quality work results.

Specifications

Standards

Milling technology

Milling drum LA15 including wear protection on the sides

BOMAG BMS 15 L exchangeable toolholder

3 Milling-Drum-speeds, 100, 112, 130

Proportional adjustable water injection, 0-12 l/min

Automatic water saving device

Levelling, 2 sides + slope

Wear-free, digital Milling depth display

Proportional Milling depth adjustment

Two proportional speeds for Milling- depth-adjustment

Hydraulically operated side-plates with 500 mm (right) and 400 mm (left) stroke

Hydraulically operated front mouldboard

Hydraulically rear mouldboard with adjustable preload-pressure

Right side-plate for fast Drum-exchange

Automatic load-control

Automatic distribution of traction

Hydraulically foldable Conveyor with +65° swivel angle

Camera system: 1x discharge belt, 1x on the back

BOMAG Dual Filtration

BOMAG Easy Cut

BOMAG Easy Level

Drive Systems

Drive Systems

4 crawler B1 size steerable, front or/and rear

Crab walk

Variable transport speed

Variable operating speed

Mechanical Drum-drive

Operation comfort

Operation comfort

Fully vibration-isolated operator-platform

Comfort zones at the standing areas for fatigueless operation

Adjustable dashboards

Standardized self-explanatory, well-arranged dashboards

Large storage at ground level

Service- and maintenance-points ergonomic concentrated

Large Storage compartment at the operator platform including 24V plug and flexible layer

Diesel and AdBlue fill comfortable and safely place at the operator station

BOMAG Fast Select for a fast machine operation

Safety & environmental protection

Safety & environmental protection

Noise optimized design

Liquid cooled engine following latest emission rules without hot exhaust jet to the back

Integrated working lights

Rotary-beacon

Mirrors

CE-conform safety-package with emergency- stop-switches

Back-up-alarm

Options

Basic machine

Track chains B3 size

Storage compartment for cutting tools on the track chains

Weather protection roof

Plexiglas weather protection for the side railings

Water filling pump

High pressure cleaner

Hose reel

Dust reduction system

ION DUST SHIELD

Auxiliary Drum Drive for easy tool exchange

Compressed air system

Additional motor for auxiliary function & emergency drive function

Additional compartment for cutting tool

Additional working-light, magnet base

Advanced lighting package – additional 142.000 lm

Ballast weights

Special colour

Biodegradable hydraulic oil

Slewable standing support

Vandalism protection

Milling technology

Milling technology

Quick-exchange drum-system

Milling-Drum 2000, BMS 15 L, LA15

Milling-Drum 2200, BMS 15 L, LA15

Milling-Drum 2000, BMS 15 L, LA8

Milling-Drum 2200, BMS 15 L, LA8

POWER DRUM 2000, BMS 15 L, LA23

POWER DRUM 2200, BMS 15 L, LA23

Additional Milling Drum Bearing

Levelling Systems and electronic support

Levelling Systems and electronic support

Additional external BOMAG Easy Level Display

2 scanners left & right in front of the milling box

Camera system: 2 additional camera’s, 1x downholder, 1x rear scraper

BOMAG TELEMATIC

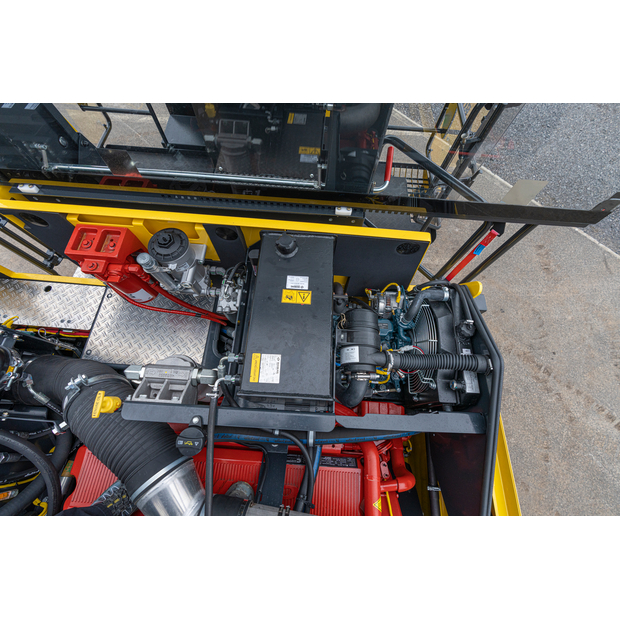

Maintenance with a concept

Maintenance, easy and fast.

Longevity and low maintenance are two essential design principles at BOMAG implemented in the smallest details, reducing service costs and non-productive time to a minimum. With BOMAG, all components for servicing are well positioned and freely accessible. This applies to tanks, service points in the engine compartment and work on the milling drum.

Emission stage: Stage V / TIER4fWeight: 59,525 lb

Performance: 630.3 hp

BM 2000/65 large planer: Simply revolutionary in the 2-metre class.

Leading the way in weight, efficiency and comfort.

BOMAG's BM 2000/65 large planer sets new standards in the 2-metre class - it is even lighter, more manoeuvrable, more cost-effective and particularly easy to operate.

The cold planer's clever design offers the operator excellent all-round visibility. A clear view of the milling edge to the front enables extremely precise milling in the track. Its slim tail improves rear visibility and hence working safety.

The BM 2000/65's sleek design results in a turning circle of only 1.7 m, making the planer highly manoeuvrable. Milling in tight bends or roundabouts is no problem with the BM 2000/65.

When milling different road surfaces, asphalt and concrete selectively, operation is intuitive. BOMAG's operating concept focuses on short navigation steps and only a few submenus. And servicing the planer is made even easier by straightforward access to all maintenance points.

Leading the way in weight, efficiency and comfort.

BOMAG's BM 2000/65 large planer sets new standards in the 2-metre class - it is even lighter, more manoeuvrable, more cost-effective and particularly easy to operate.

The cold planer's clever design offers the operator excellent all-round visibility. A clear view of the milling edge to the front enables extremely precise milling in the track. Its slim tail improves rear visibility and hence working safety.

The BM 2000/65's sleek design results in a turning circle of only 1.7 m, making the planer highly manoeuvrable. Milling in tight bends or roundabouts is no problem with the BM 2000/65.

When milling different road surfaces, asphalt and concrete selectively, operation is intuitive. BOMAG's operating concept focuses on short navigation steps and only a few submenus. And servicing the planer is made even easier by straightforward access to all maintenance points.

Fields of application

Asphalt milling is a method for removing specified layers of asphalt road pavements.

BOMAG cold milling machines are designed for selective milling of lane and ground linings made up of a wide range of asphalt and concrete compounds. The different models are particularly suited for repairs or the complete removal of motorways and major federal roads, and for rural roads and inner-city work including work on roundabouts. With different working and milling depths, large areas can be removed quickly and completely in one work stage.

Technology makes the difference.

BOMAG consistently sets industry standards and has developed numerous technologies that make everyday work easier, support machine operators and ensure high-quality work results.

Specifications

Standards

Milling technology

Milling drum LA15 including wear protection on the sides

BOMAG BMS 15 L exchangeable toolholder

3 Milling-Drum-speeds, 100, 112, 130

Proportional adjustable water injection, 0-12 l/min

Automatic water saving device

Levelling, 2 sides + slope

Wear-free, digital Milling depth display

Proportional Milling depth adjustment

Two proportional speeds for Milling- depth-adjustment

Hydraulically operated side-plates with 500 mm (right) and 400 mm (left) stroke

Hydraulically operated front mouldboard

Hydraulically rear mouldboard with adjustable preload-pressure

Right side-plate for fast Drum-exchange

Automatic load-control

Automatic distribution of traction

Hydraulically foldable Conveyor with +65° swivel angle

Camera system: 1x discharge belt, 1x on the back

BOMAG Dual Filtration

BOMAG Easy Cut

BOMAG Easy Level

Drive Systems

Drive Systems

4 crawler B1 size steerable, front or/and rear

Crab walk

Variable transport speed

Variable operating speed

Mechanical Drum-drive

Operation comfort

Operation comfort

Fully vibration-isolated operator-platform

Comfort zones at the standing areas for fatigueless operation

Adjustable dashboards

Standardized self-explanatory, well-arranged dashboards

Large storage at ground level

Service- and maintenance-points ergonomic concentrated

Large Storage compartment at the operator platform including 24V plug and flexible layer

Diesel and AdBlue fill comfortable and safely place at the operator station

BOMAG Fast Select for a fast machine operation

Safety & environmental protection

Safety & environmental protection

Noise optimized design

Liquid cooled engine following latest emission rules without hot exhaust jet to the back

Integrated working lights

Rotary-beacon

Mirrors

CE-conform safety-package with emergency- stop-switches

Back-up-alarm

Options

Basic machine

Track chains B3 size

Storage compartment for cutting tools on the track chains

Weather protection roof

Plexiglas weather protection for the side railings

Water filling pump

High pressure cleaner

Hose reel

Dust reduction system

ION DUST SHIELD

Auxiliary Drum Drive for easy tool exchange

Compressed air system

Additional motor for auxiliary function & emergency drive function

Additional compartment for cutting tool

Additional working-light, magnet base

Advanced lighting package – additional 142.000 lm

Ballast weights

Special colour

Biodegradable hydraulic oil

Slewable standing support

Vandalism protection

Milling technology

Milling technology

Quick-exchange drum-system

Milling-Drum 2000, BMS 15 L, LA15

Milling-Drum 2200, BMS 15 L, LA15

Milling-Drum 2000, BMS 15 L, LA8

Milling-Drum 2200, BMS 15 L, LA8

POWER DRUM 2000, BMS 15 L, LA23

POWER DRUM 2200, BMS 15 L, LA23

Additional Milling Drum Bearing

Levelling Systems and electronic support

Levelling Systems and electronic support

Additional external BOMAG Easy Level Display

2 scanners left & right in front of the milling box

Camera system: 2 additional camera’s, 1x downholder, 1x rear scraper

BOMAG TELEMATIC

Maintenance with a concept

Maintenance, easy and fast.

Longevity and low maintenance are two essential design principles at BOMAG implemented in the smallest details, reducing service costs and non-productive time to a minimum. With BOMAG, all components for servicing are well positioned and freely accessible. This applies to tanks, service points in the engine compartment and work on the milling drum.

Weight: 59,525 lb

Performance: 630.3 hp

BM 2000/65 large planer: Simply revolutionary in the 2-metre class.

Leading the way in weight, efficiency and comfort.

BOMAG's BM 2000/65 large planer sets new standards in the 2-metre class - it is even lighter, more manoeuvrable, more cost-effective and particularly easy to operate.

The cold planer's clever design offers the operator excellent all-round visibility. A clear view of the milling edge to the front enables extremely precise milling in the track. Its slim tail improves rear visibility and hence working safety.

The BM 2000/65's sleek design results in a turning circle of only 1.7 m, making the planer highly manoeuvrable. Milling in tight bends or roundabouts is no problem with the BM 2000/65.

When milling different road surfaces, asphalt and concrete selectively, operation is intuitive. BOMAG's operating concept focuses on short navigation steps and only a few submenus. And servicing the planer is made even easier by straightforward access to all maintenance points.

Leading the way in weight, efficiency and comfort.

BOMAG's BM 2000/65 large planer sets new standards in the 2-metre class - it is even lighter, more manoeuvrable, more cost-effective and particularly easy to operate.

The cold planer's clever design offers the operator excellent all-round visibility. A clear view of the milling edge to the front enables extremely precise milling in the track. Its slim tail improves rear visibility and hence working safety.

The BM 2000/65's sleek design results in a turning circle of only 1.7 m, making the planer highly manoeuvrable. Milling in tight bends or roundabouts is no problem with the BM 2000/65.

When milling different road surfaces, asphalt and concrete selectively, operation is intuitive. BOMAG's operating concept focuses on short navigation steps and only a few submenus. And servicing the planer is made even easier by straightforward access to all maintenance points.

Fields of application

Asphalt milling is a method for removing specified layers of asphalt road pavements.

BOMAG cold milling machines are designed for selective milling of lane and ground linings made up of a wide range of asphalt and concrete compounds. The different models are particularly suited for repairs or the complete removal of motorways and major federal roads, and for rural roads and inner-city work including work on roundabouts. With different working and milling depths, large areas can be removed quickly and completely in one work stage.

Technology makes the difference.

BOMAG consistently sets industry standards and has developed numerous technologies that make everyday work easier, support machine operators and ensure high-quality work results.

Specifications

Standards

Milling technology

Milling drum LA15 including wear protection on the sides

BOMAG BMS 15 L exchangeable toolholder

3 Milling-Drum-speeds, 100, 112, 130

Proportional adjustable water injection, 0-12 l/min

Automatic water saving device

Levelling, 2 sides + slope

Wear-free, digital Milling depth display

Proportional Milling depth adjustment

Two proportional speeds for Milling- depth-adjustment

Hydraulically operated side-plates with 500 mm (right) and 400 mm (left) stroke

Hydraulically operated front mouldboard

Hydraulically rear mouldboard with adjustable preload-pressure

Right side-plate for fast Drum-exchange

Automatic load-control

Automatic distribution of traction

Hydraulically foldable Conveyor with +65° swivel angle

Camera system: 1x discharge belt, 1x on the back

BOMAG Dual Filtration

BOMAG Easy Cut

BOMAG Easy Level

Drive Systems

Drive Systems

4 crawler B1 size steerable, front or/and rear

Crab walk

Variable transport speed

Variable operating speed

Mechanical Drum-drive

Operation comfort

Operation comfort

Fully vibration-isolated operator-platform

Comfort zones at the standing areas for fatigueless operation

Adjustable dashboards

Standardized self-explanatory, well-arranged dashboards

Large storage at ground level

Service- and maintenance-points ergonomic concentrated

Large Storage compartment at the operator platform including 24V plug and flexible layer

Diesel and AdBlue fill comfortable and safely place at the operator station

BOMAG Fast Select for a fast machine operation

Safety & environmental protection

Safety & environmental protection

Noise optimized design

Liquid cooled engine following latest emission rules without hot exhaust jet to the back

Integrated working lights

Rotary-beacon

Mirrors

CE-conform safety-package with emergency- stop-switches

Back-up-alarm

Options

Basic machine

Track chains B3 size

Storage compartment for cutting tools on the track chains

Weather protection roof

Plexiglas weather protection for the side railings

Water filling pump

High pressure cleaner

Hose reel

Dust reduction system

ION DUST SHIELD

Auxiliary Drum Drive for easy tool exchange

Compressed air system

Additional motor for auxiliary function & emergency drive function

Additional compartment for cutting tool

Additional working-light, magnet base

Advanced lighting package – additional 142.000 lm

Ballast weights

Special colour

Biodegradable hydraulic oil

Slewable standing support

Vandalism protection

Milling technology

Milling technology

Quick-exchange drum-system

Milling-Drum 2000, BMS 15 L, LA15

Milling-Drum 2200, BMS 15 L, LA15

Milling-Drum 2000, BMS 15 L, LA8

Milling-Drum 2200, BMS 15 L, LA8

POWER DRUM 2000, BMS 15 L, LA23

POWER DRUM 2200, BMS 15 L, LA23

Additional Milling Drum Bearing

Levelling Systems and electronic support

Levelling Systems and electronic support

Additional external BOMAG Easy Level Display

2 scanners left & right in front of the milling box

Camera system: 2 additional camera’s, 1x downholder, 1x rear scraper

BOMAG TELEMATIC

Maintenance with a concept

Maintenance, easy and fast.

Longevity and low maintenance are two essential design principles at BOMAG implemented in the smallest details, reducing service costs and non-productive time to a minimum. With BOMAG, all components for servicing are well positioned and freely accessible. This applies to tanks, service points in the engine compartment and work on the milling drum.

Show more Show less

Construction Equipment

Construction Equipment

Cranes

Cranes

Material Handling

Material Handling

Trucks & Trailers

Trucks & Trailers

Vehicles

Vehicles

Agricultural Equipment

Agricultural Equipment

Live Auctions

Live Auctions