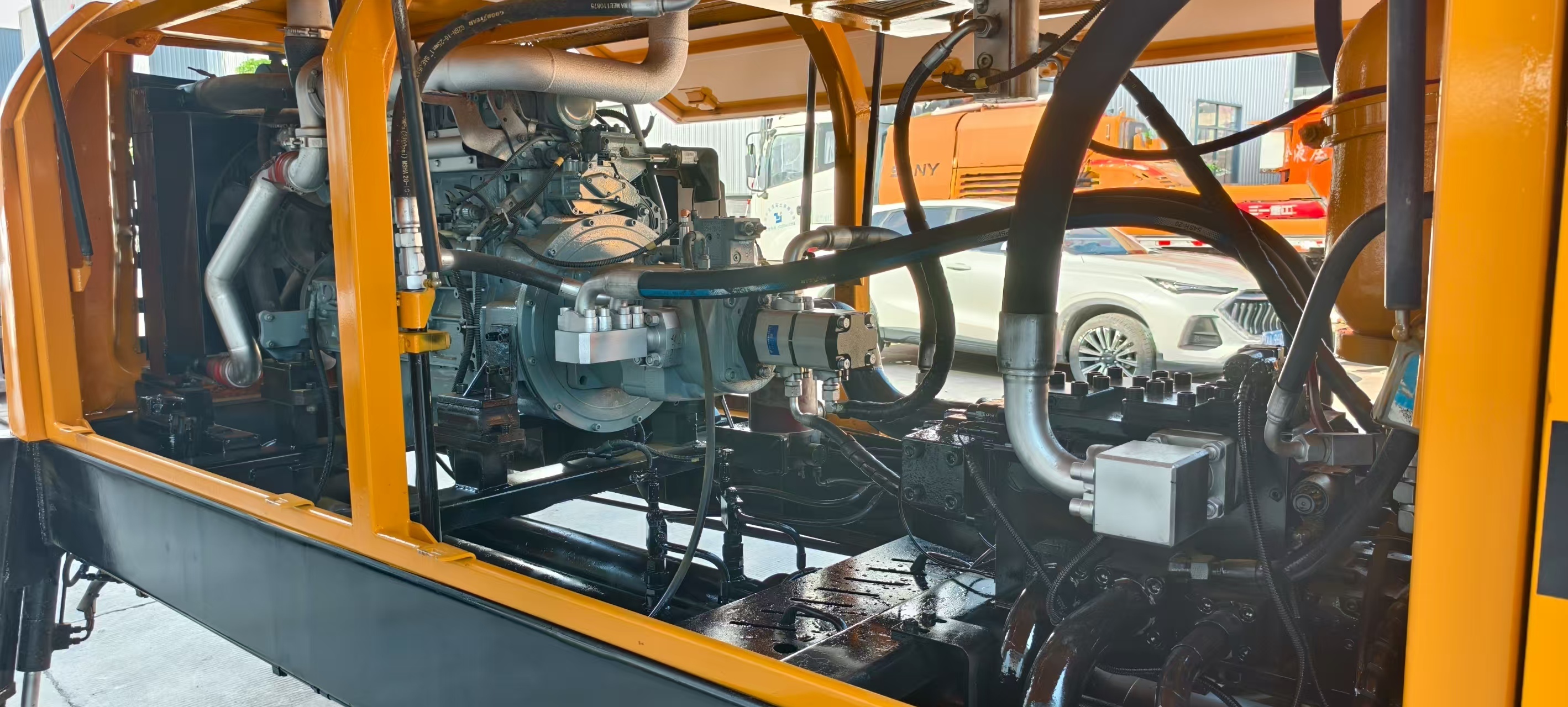

2025 Sany HBT80C

Year

Year

2025

Hrs.

Hrs.

203

Condition

Condition

New

Overview

Description

Main advantages of concrete pumps

🚀 1. High delivery efficiency and fast construction speed

Can continuously deliver concrete to long distances or high altitudes

Large delivery volume, suitable for large-volume concrete construction

Compared with manual or lifting machinery methods, it saves more time and manpower

📏 2. Long pumping distance, adaptable to a variety of construction site environments

Horizontal delivery can reach hundreds of meters, and height delivery can reach tens to hundreds of meters (depending on the model)

Especially suitable for complex terrain conditions such as high-rise buildings, tunnels, and bridges

Flexible pipeline layout and strong adaptability

🧱 3. More uniform concrete pouring and better quality

Continuous delivery avoids problems such as concrete stratification, segregation, and cold joints

Stable delivery pressure is beneficial to the overall density of the structure

More standardized construction technology and more reliable quality

👷 4. Save manpower and improve safety

Only a few operators are needed to complete large-scale pouring operations

Avoid the high risk of manual lifting and hoisting

Reduce construction site labor costs and accident probability

🧰 5. Easy maintenance and high equipment reliability

Most brands are equipped with automatic lubrication systems and intelligent control panels

Core components such as pistons and pump cylinders are wear-resistant and have a long lifespan

Low failure rate and easy daily maintenance

Main advantages of concrete pumps

🚀 1. High delivery efficiency and fast construction speed

Can continuously deliver concrete to long distances or high altitudes

Large delivery volume, suitable for large-volume concrete construction

Compared with manual or lifting machinery methods, it saves more time and manpower

📏 2. Long pumping distance, adaptable to a variety of construction site environments

Horizontal delivery can reach hundreds of meters, and height delivery can reach tens to hundreds of meters (depending on the model)

Especially suitable for complex terrain conditions such as high-rise buildings, tunnels, and bridges

Flexible pipeline layout and strong adaptability

🧱 3. More uniform concrete pouring and better quality

Continuous delivery avoids problems such as concrete stratification, segregation, and cold joints

Stable delivery pressure is beneficial to the overall density of the structure

More standardized construction technology and more reliable quality

👷 4. Save manpower and improve safety

Only a few operators are needed to complete large-scale pouring operations

Avoid the high risk of manual lifting and hoisting

Reduce construction site labor costs and accident probability

🧰 5. Easy maintenance and high equipment reliability

Most brands are equipped with automatic lubrication systems and intelligent control panels

Core components such as pistons and pump cylinders are wear-resistant and have a long lifespan

Low failure rate and easy daily maintenance

🚀 1. High delivery efficiency and fast construction speed

Can continuously deliver concrete to long distances or high altitudes

Large delivery volume, suitable for large-volume concrete construction

Compared with manual or lifting machinery methods, it saves more time and manpower

📏 2. Long pumping distance, adaptable to a variety of construction site environments

Horizontal delivery can reach hundreds of meters, and height delivery can reach tens to hundreds of meters (depending on the model)

Especially suitable for complex terrain conditions such as high-rise buildings, tunnels, and bridges

Flexible pipeline layout and strong adaptability

🧱 3. More uniform concrete pouring and better quality

Continuous delivery avoids problems such as concrete stratification, segregation, and cold joints

Stable delivery pressure is beneficial to the overall density of the structure

More standardized construction technology and more reliable quality

👷 4. Save manpower and improve safety

Only a few operators are needed to complete large-scale pouring operations

Avoid the high risk of manual lifting and hoisting

Reduce construction site labor costs and accident probability

🧰 5. Easy maintenance and high equipment reliability

Most brands are equipped with automatic lubrication systems and intelligent control panels

Core components such as pistons and pump cylinders are wear-resistant and have a long lifespan

Low failure rate and easy daily maintenance

Show more Show less

Construction Equipment

Construction Equipment

Cranes

Cranes

Material Handling

Material Handling

Trucks & Trailers

Trucks & Trailers

Vehicles

Vehicles

Agricultural Equipment

Agricultural Equipment

Live Auctions

Live Auctions