بوماج BF 300 C-2

بوماج BF 300 C-2

حالة المعدة

حالة المعدة

مستعملة

نظرة عامة

الوصف

Emission stage: Stage V / TIER4f

Weight: 19,842 lb

Working width (min-max): 66.9 - 196.9 in

City paver BF 300 C-2: Born for the road.

City paver: Excellent on small construction sites.

Compact, strong, reliable: Our small machines know their trade just as well as their big brothers and are characterized especially by their flexibility. Ideal for use on confined construction sites.

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

City paver: Excellent on small construction sites.

Compact, strong, reliable: Our small machines know their trade just as well as their big brothers and are characterized especially by their flexibility. Ideal for use on confined construction sites.

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Fields of application

Asphalt paving with BOMAG pavers guarantees the highest efficiency and quality in road construction.

With BOMAG pavers you can choose the optimal road paver for your application from a wide range of products (5-21 t). We offer a vast array of machines and equipment from the flexibly-deployable pedestrian road paver to the heavy-duty paver.

Technology makes the difference.

BOMAG consistently sets industry standards and has developed numerous technologies that make everyday work easier, support machine operators and ensure high-quality work results.

Specifications

Standards

Operator compartment

SIDEVIEW

Driver‘s seat: with swivel and side-shift

Dashboard protection

Hydraulic hinged roof

Digital display for machine Management

Tractor

Tractor

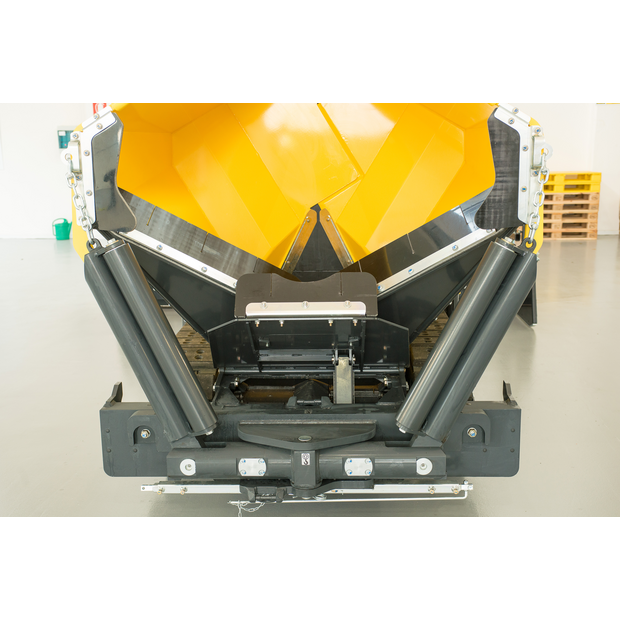

ECOMODE

Separate control of hopper wings

Hydraulic, height adjustable auger

Track scraper

2 proportionally controlled and reversible wear-resistant cast augers, screw blades separately replaceable

2 independent and reversible scraper belts, high-wear resistant plates

Rubber track pads

Screed

Screed

L.C.S. Screed relief and traction increase system

Screed temperature control

MAGMALIFE Aluminium heating plates

MAGMALIFE Automatic screed heating

Mechanical screed lock

Crown adjustment

Side control of auger/scraper belts

Other

Other

Tools

8 work lights

Three phase Generator

Socket 2 x 240 volt

Options

Operator compartment

Weather protection for platform

Seat warmer

Asphalt steam extraction

Tractor

Tractor

Central lubrication system

Optional paint finish

Biologically degradable hydraulic oil

Hydraulic hopper front flap

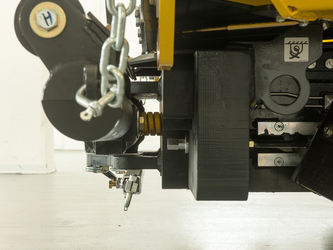

Spring dampened push rollers

Screed

Screed

Hydraulic crown adjustment

Heated side plates

S 340-2 extensions: 350 mm, 500 mm

Reduction shoes

Levelling systems

Levelling systems

Height and cross-slope sensing by means of ultrasonic or mechanical sensors

Other

Other

Fleetmanagement BOMAG TELEMATIC

Moon-light balloon

LED working lights

Maintenance with a concept

Virtually maintenance-free.

The simplest and most cost-effective service is the one that isn’t necessary. The maintenance of our road pavers is as simple as their operation. As every function is controlled by its own switch, every switch can also be replaced separately. The engine compartment with the hydraulic systems is easily accessible from every side, and all the filters can be reached comfortably and centrally from one side. Good ideas, such as the fully automated central lubrication system, contribute to the remarkably long maintenance intervals of our pavers. To keep any downtimes as short as possible, we offer carefully selected maintenance and emergency kits.

Guaranteed quality and reliability.

BOMAG quality

BOMAG support and training

BOMAG fleet management

BOMAG Service Kits

If the label says BOMAG, you can expect top quality. This applies as much to the built-in machine components as it does to Original BOMAG spare parts and BOMAG service. We want your pavers and feeders to keep running.

High-quality wear parts ensure a particularly long service life for BOMAG pavers and feeders. The tamper bars are fully hardened, and the screed plates are made of 15 mm thick, wear-resistant steel (Brinell hardness 450).

Our online and classroom training sessions provide valuable know-how for everyday tasks. And you can also rely on our application engineers in an emergency – because they are on the road throughout the world.

Position, fuel consumption, operating hours – discover the hidden potential that enables you to use pavers and feeders even more efficiently. Your machines are just a mouse click away.

BOMAG supplies everything you need for maintenance, wear repairs or daily on-site servicing: operating fluids and Genuine Parts, tailor-made for every BOMAG feeder and paver. Reduce the risk of downtime to a minimum.

Emission stage: Stage V / TIER4fWeight: 19,842 lb

Working width (min-max): 66.9 - 196.9 in

City paver BF 300 C-2: Born for the road.

City paver: Excellent on small construction sites.

Compact, strong, reliable: Our small machines know their trade just as well as their big brothers and are characterized especially by their flexibility. Ideal for use on confined construction sites.

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

City paver: Excellent on small construction sites.

Compact, strong, reliable: Our small machines know their trade just as well as their big brothers and are characterized especially by their flexibility. Ideal for use on confined construction sites.

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Fields of application

Asphalt paving with BOMAG pavers guarantees the highest efficiency and quality in road construction.

With BOMAG pavers you can choose the optimal road paver for your application from a wide range of products (5-21 t). We offer a vast array of machines and equipment from the flexibly-deployable pedestrian road paver to the heavy-duty paver.

Technology makes the difference.

BOMAG consistently sets industry standards and has developed numerous technologies that make everyday work easier, support machine operators and ensure high-quality work results.

Specifications

Standards

Operator compartment

SIDEVIEW

Driver‘s seat: with swivel and side-shift

Dashboard protection

Hydraulic hinged roof

Digital display for machine Management

Tractor

Tractor

ECOMODE

Separate control of hopper wings

Hydraulic, height adjustable auger

Track scraper

2 proportionally controlled and reversible wear-resistant cast augers, screw blades separately replaceable

2 independent and reversible scraper belts, high-wear resistant plates

Rubber track pads

Screed

Screed

L.C.S. Screed relief and traction increase system

Screed temperature control

MAGMALIFE Aluminium heating plates

MAGMALIFE Automatic screed heating

Mechanical screed lock

Crown adjustment

Side control of auger/scraper belts

Other

Other

Tools

8 work lights

Three phase Generator

Socket 2 x 240 volt

Options

Operator compartment

Weather protection for platform

Seat warmer

Asphalt steam extraction

Tractor

Tractor

Central lubrication system

Optional paint finish

Biologically degradable hydraulic oil

Hydraulic hopper front flap

Spring dampened push rollers

Screed

Screed

Hydraulic crown adjustment

Heated side plates

S 340-2 extensions: 350 mm, 500 mm

Reduction shoes

Levelling systems

Levelling systems

Height and cross-slope sensing by means of ultrasonic or mechanical sensors

Other

Other

Fleetmanagement BOMAG TELEMATIC

Moon-light balloon

LED working lights

Maintenance with a concept

Virtually maintenance-free.

The simplest and most cost-effective service is the one that isn’t necessary. The maintenance of our road pavers is as simple as their operation. As every function is controlled by its own switch, every switch can also be replaced separately. The engine compartment with the hydraulic systems is easily accessible from every side, and all the filters can be reached comfortably and centrally from one side. Good ideas, such as the fully automated central lubrication system, contribute to the remarkably long maintenance intervals of our pavers. To keep any downtimes as short as possible, we offer carefully selected maintenance and emergency kits.

Guaranteed quality and reliability.

BOMAG quality

BOMAG support and training

BOMAG fleet management

BOMAG Service Kits

If the label says BOMAG, you can expect top quality. This applies as much to the built-in machine components as it does to Original BOMAG spare parts and BOMAG service. We want your pavers and feeders to keep running.

High-quality wear parts ensure a particularly long service life for BOMAG pavers and feeders. The tamper bars are fully hardened, and the screed plates are made of 15 mm thick, wear-resistant steel (Brinell hardness 450).

Our online and classroom training sessions provide valuable know-how for everyday tasks. And you can also rely on our application engineers in an emergency – because they are on the road throughout the world.

Position, fuel consumption, operating hours – discover the hidden potential that enables you to use pavers and feeders even more efficiently. Your machines are just a mouse click away.

BOMAG supplies everything you need for maintenance, wear repairs or daily on-site servicing: operating fluids and Genuine Parts, tailor-made for every BOMAG feeder and paver. Reduce the risk of downtime to a minimum.

Weight: 19,842 lb

Working width (min-max): 66.9 - 196.9 in

City paver BF 300 C-2: Born for the road.

City paver: Excellent on small construction sites.

Compact, strong, reliable: Our small machines know their trade just as well as their big brothers and are characterized especially by their flexibility. Ideal for use on confined construction sites.

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

City paver: Excellent on small construction sites.

Compact, strong, reliable: Our small machines know their trade just as well as their big brothers and are characterized especially by their flexibility. Ideal for use on confined construction sites.

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Powerful yet economical: the 55 kw engine in tandem with ECOMODE engine management

MAGMALIFE heating elements for a longer service life and even heat distribution

Particularly user-friendly with the BOMAG SIDEVIEW system

Laying widths of up to 16 ft possible

Fields of application

Asphalt paving with BOMAG pavers guarantees the highest efficiency and quality in road construction.

With BOMAG pavers you can choose the optimal road paver for your application from a wide range of products (5-21 t). We offer a vast array of machines and equipment from the flexibly-deployable pedestrian road paver to the heavy-duty paver.

Technology makes the difference.

BOMAG consistently sets industry standards and has developed numerous technologies that make everyday work easier, support machine operators and ensure high-quality work results.

Specifications

Standards

Operator compartment

SIDEVIEW

Driver‘s seat: with swivel and side-shift

Dashboard protection

Hydraulic hinged roof

Digital display for machine Management

Tractor

Tractor

ECOMODE

Separate control of hopper wings

Hydraulic, height adjustable auger

Track scraper

2 proportionally controlled and reversible wear-resistant cast augers, screw blades separately replaceable

2 independent and reversible scraper belts, high-wear resistant plates

Rubber track pads

Screed

Screed

L.C.S. Screed relief and traction increase system

Screed temperature control

MAGMALIFE Aluminium heating plates

MAGMALIFE Automatic screed heating

Mechanical screed lock

Crown adjustment

Side control of auger/scraper belts

Other

Other

Tools

8 work lights

Three phase Generator

Socket 2 x 240 volt

Options

Operator compartment

Weather protection for platform

Seat warmer

Asphalt steam extraction

Tractor

Tractor

Central lubrication system

Optional paint finish

Biologically degradable hydraulic oil

Hydraulic hopper front flap

Spring dampened push rollers

Screed

Screed

Hydraulic crown adjustment

Heated side plates

S 340-2 extensions: 350 mm, 500 mm

Reduction shoes

Levelling systems

Levelling systems

Height and cross-slope sensing by means of ultrasonic or mechanical sensors

Other

Other

Fleetmanagement BOMAG TELEMATIC

Moon-light balloon

LED working lights

Maintenance with a concept

Virtually maintenance-free.

The simplest and most cost-effective service is the one that isn’t necessary. The maintenance of our road pavers is as simple as their operation. As every function is controlled by its own switch, every switch can also be replaced separately. The engine compartment with the hydraulic systems is easily accessible from every side, and all the filters can be reached comfortably and centrally from one side. Good ideas, such as the fully automated central lubrication system, contribute to the remarkably long maintenance intervals of our pavers. To keep any downtimes as short as possible, we offer carefully selected maintenance and emergency kits.

Guaranteed quality and reliability.

BOMAG quality

BOMAG support and training

BOMAG fleet management

BOMAG Service Kits

If the label says BOMAG, you can expect top quality. This applies as much to the built-in machine components as it does to Original BOMAG spare parts and BOMAG service. We want your pavers and feeders to keep running.

High-quality wear parts ensure a particularly long service life for BOMAG pavers and feeders. The tamper bars are fully hardened, and the screed plates are made of 15 mm thick, wear-resistant steel (Brinell hardness 450).

Our online and classroom training sessions provide valuable know-how for everyday tasks. And you can also rely on our application engineers in an emergency – because they are on the road throughout the world.

Position, fuel consumption, operating hours – discover the hidden potential that enables you to use pavers and feeders even more efficiently. Your machines are just a mouse click away.

BOMAG supplies everything you need for maintenance, wear repairs or daily on-site servicing: operating fluids and Genuine Parts, tailor-made for every BOMAG feeder and paver. Reduce the risk of downtime to a minimum.

أظهر المزيد عرض أقل

معدات ثقيلة

معدات ثقيلة

كرينات

كرينات

مناولة العتاد

مناولة العتاد

الشاحنات والمقطورات

الشاحنات والمقطورات

مركبة تجارية

مركبة تجارية

معدات الزراعية

معدات الزراعية

مزادات مباشرة

مزادات مباشرة